Views: 0 Author: Site Editor Publish Time: 2025-10-01 Origin: Site

Building a running track can be costly. Understanding the factors that influence the cost of running track installation is crucial for any project. In this article, we'll break down the various elements that impact track construction costs, such as size, surface materials, and site preparation. By the end, you’ll have a clear understanding of how to plan for and budget a running track installation project.

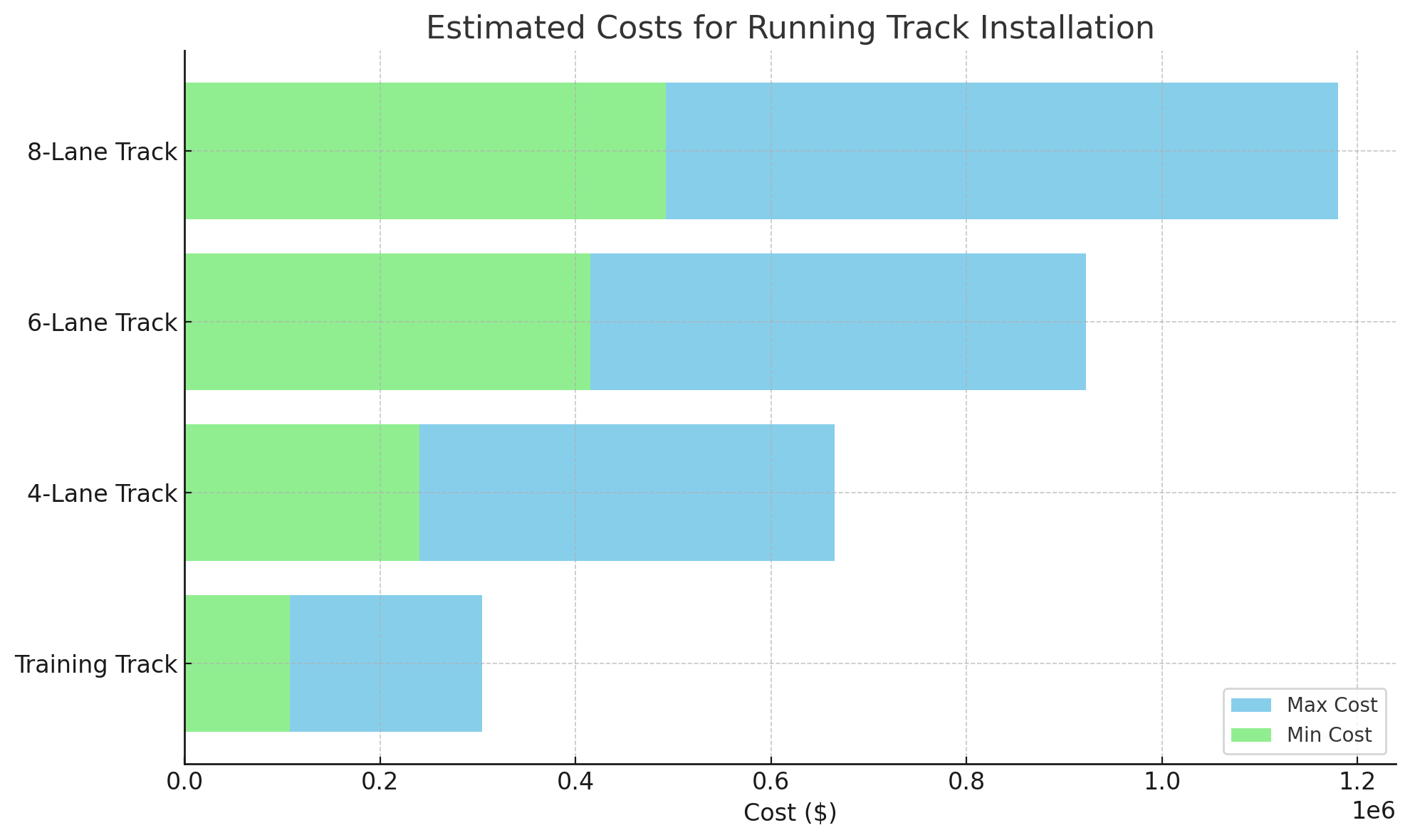

The size of the track is one of the most significant factors in running track installation. A standard 400-meter track will be more expensive than smaller alternatives, as it requires more materials and labor to construct. Typically, the costs increase as the track size expands. For instance:

● 4-lane track: $240,000 – $665,000

● 6-lane track: $415,000 – $922,000

● 8-lane track: $492,000 – $1,180,000

Larger tracks also require more equipment and longer construction times, further adding to the overall cost. Additionally, tracks used for professional competitions may require specific design specifications that drive up the cost.

The choice of surface material significantly impacts the cost of running track installation. The most common materials used are:

● Polyurethane: High-performance material that provides durability and a smooth running surface. However, it comes with a higher upfront cost.

● Synthetic Rubber: More affordable, but may require more frequent resurfacing.

● EPDM Rubber: Offers vibrant colors and weather resistance but is moderately priced.

Each surface material offers different levels of performance, longevity, and maintenance costs. While polyurethane provides excellent performance for professional tracks, its higher price might be out of reach for budget-conscious projects.

The state of the construction site also influences installation costs. Sites with poor soil conditions require additional work for grading, excavation, and soil stabilization. Preparing a solid base layer and ensuring proper drainage systems are in place is crucial to prevent future issues with the track’s integrity.

In some cases, more expensive site preparation and soil surveys may be necessary to meet the requirements of the track. For example, poorly draining sites will need more advanced drainage solutions, increasing overall costs.

The basic costs for running track installation depend largely on the track's size, surface material, and site conditions. Below is a general breakdown:

● Training track (10,400 square feet): $108,000 – $304,000

● 4-lane track (26,000 square feet): $240,000 – $665,000

● 6-lane track (38,000 square feet): $415,000 – $922,000

● 8-lane track (49,500 square feet): $492,000 – $1,180,000

These figures represent the costs for basic construction, including the base layer and surface material installation. However, additional costs like drainage, lighting, or customization will add to the final price.

In addition to basic construction, several optional features contribute to the overall cost. These include:

● Drainage Systems: Proper drainage is essential to prevent water damage, and the cost can vary depending on the complexity and location.

● Lighting: Installing lighting for evening use adds to the cost, especially if high-performance lighting is required for professional events.

● Track Striping: Accurate lane markings are necessary for competitive events and come at an added cost, depending on the track’s size.

Customization options, such as adding seating or scoreboards, can further increase costs but enhance the functionality of the track.

Labor costs are highly dependent on the geographic location and the contractor's experience. Areas with high demand for construction services tend to have higher labor costs. Additionally, more experienced contractors who specialize in running track installation may charge a premium, but they often provide better quality and faster completion times.

It’s important to gather multiple quotes from contractors to ensure competitive pricing and evaluate the experience and reputation of the company handling your project.

While the upfront cost of building a running track can be significant, investing in a high-quality, durable track offers long-term benefits. A professionally installed track that meets high standards will require fewer repairs, reducing the need for costly maintenance over time. Polyurethane tracks, for instance, offer exceptional durability and require less frequent resurfacing, making them a solid long-term investment.

Well-maintained tracks attract more events, increasing the facility’s usage and, in turn, providing better returns on the initial investment.

Maintenance costs are an essential part of the overall cost consideration. For a well-constructed track, annual maintenance typically ranges from $15,000 to $30,000 for an 8-lane track. Maintenance tasks include regular cleaning, repairs, and resurfacing. The frequency of resurfacing depends on the surface material, with some materials requiring resurfacing every 5-7 years, while others may last up to 10 years.

Planning for these recurring costs ensures that the track remains in top condition for many years, preserving its value and functionality.

A running track cost calculator can help you estimate the expenses for your track installation project. By inputting key details, such as track size, surface material, and location, the calculator provides an estimate that helps in budgeting for the project.

This tool is valuable for planning and comparing costs for different surface options and track configurations. It gives you a clearer picture of the financial commitment involved before proceeding with the project.

While a cost calculator offers a good starting point, it’s essential to consult professional contractors for a more accurate estimate. They can evaluate your site’s specific conditions and provide a customized quote that accounts for any unique requirements, such as site preparation or drainage solutions.

Building a running track is an investment in both infrastructure and community engagement. A high-quality track provides lasting value by supporting athletes and hosting events, which can increase revenue for schools or sports complexes. Tracks are also hubs for physical activity, contributing to the overall health and well-being of the community.

Track construction projects can be costly, but there are various ways to finance the project. Many sports facilities secure funding through grants, donations, or fundraising efforts. Some organizations may also find financial support through partnerships or sponsorships.

It’s important to explore all financing options and work within your budget to ensure that the track meets both your immediate needs and long-term goals.

In conclusion, running track installation is a major investment that requires careful planning and budgeting. The cost of building a track varies based on size, surface material, site conditions, and labor costs. By understanding the factors that influence these costs and using tools like cost calculators, you can make informed decisions and plan for a successful track construction project. Consulting with experienced professionals will ensure that the track is built to high standards, offering long-lasting value for athletes, schools, and sports organizations.

Huadongtrack provides top-quality solutions for running track installation, ensuring durability and performance. Their expertise guarantees the successful completion of track projects.

A: The cost of running track installation is influenced by factors such as track size, surface material, site conditions, and labor costs.

A: A standard 400-meter running track installation typically costs between $240,000 and $1.2 million, depending on size and material.

A: Site preparation ensures a stable foundation and proper drainage, which are essential for the longevity and safety of the track, affecting the overall cost.

A: Yes, additional costs may include drainage systems, lighting, striping, and contractor fees, which can significantly affect the final price.

A: Opting for less expensive materials, smaller track sizes, or simpler designs can help lower costs while still meeting project needs.