Views: 0 Author: Site Editor Publish Time: 2025-05-23 Origin: Site

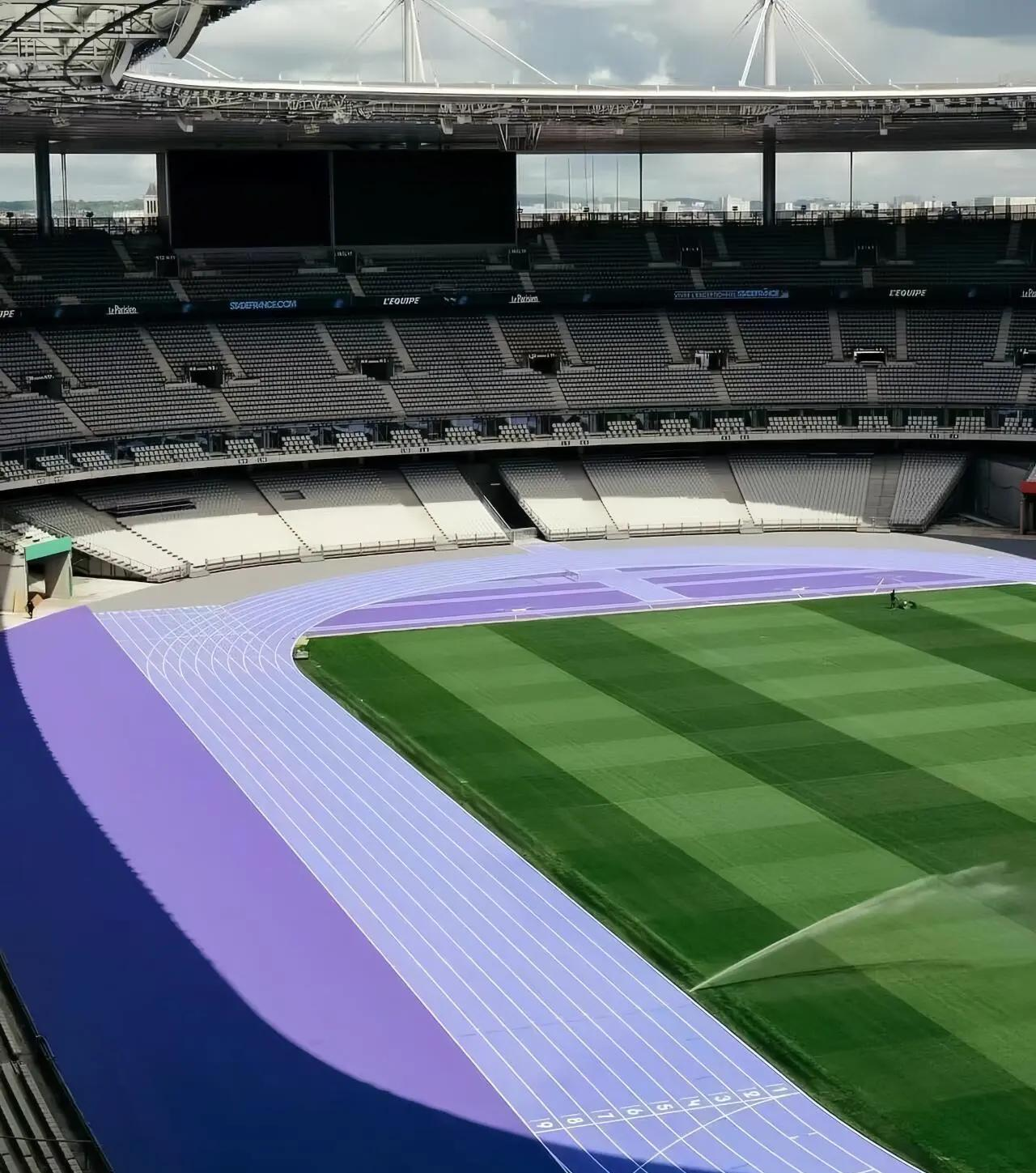

As the world turns its eyes to the Paris 2024 Olympic Games, one unusual visual element is turning heads: the striking purple hue of the athletics track. But why choose purple, a color so rarely associated with sporting surfaces? The answer lies in a combination of symbolism, branding, and innovation.

Purple is historically associated with royalty, prestige, and uniqueness. The Paris Olympic committee sought to differentiate this year’s games with a bold aesthetic that would be both iconic and memorable. Moreover, purple aligns with Paris' branding palette for the Games, aiming to unify event venues, marketing campaigns, and broadcast visuals. However, there’s more than visual flair to this choice — it also represents a commitment to sustainability and cutting-edge technology.

The purple track in Paris is more than a color statement; it’s a symbol of innovation in sustainable sports infrastructure. For the first time in Olympic history, the running track has been made with over 50% recycled and renewable materials. This includes recycled rubber composite material sourced from waste tires and industrial rubber scraps. Such initiatives help reduce resource consumption and environmental impact.

The track’s design and materials reflect a push toward greener sporting events. Developed using a low-carbon manufacturing process, this sustainable prefabricated running track significantly reduces emissions during production. It's also been verified by international carbon footprint management systems, ensuring transparency and accountability.

Athletes are, understandably, highly attuned to the performance characteristics of the surfaces they compete on. Fortunately, early feedback from test events and training sessions on the Paris purple track has been overwhelmingly positive. The track offers an optimal balance of energy return, shock absorption, and surface grip.

Thanks to bio-based rubber technology replacing traditional petroleum-based materials, the surface maintains elite-level responsiveness while being more environmentally friendly. Additionally, the longevity-optimized design ensures consistent performance over time, which is critical for athlete safety and competitive fairness.

More importantly, athletes are becoming vocal supporters of sustainability in sports. Knowing their performances contribute to a more sustainable future has resonated with many, adding a layer of moral motivation to their Olympic aspirations.

Yes, although the classic red or orange track has long been the standard, variations have occurred. For instance, the 2016 Rio Olympics featured a blue track, while the 2004 Athens Games opted for a shade of green. However, the 2024 purple track marks the boldest color shift yet and is the first to align so closely with sustainability.

(The 2004 Athens Olympics)

This track's production underscores a paradigm shift in global sporting infrastructure — one that prioritizes eco-consciousness without sacrificing quality. It's a visual and technical landmark for sustainable prefabricated running tracks worldwide.

Olympic tracks are typically made from synthetic rubber materials that provide durability, shock absorption, and traction. However, the Paris 2024 track sets a new benchmark in material innovation.

The main component is a sustainable prefabricated running track made from recycled rubber composite material. This includes ground-up waste tires and reclaimed industrial rubber. Binding agents derived from bio-based rubber technology replace petrochemical alternatives, further reducing the ecological impact.

(Recycled rubber composite material)

Moreover, the track incorporates plant-derived alternatives to petroleum-based binders. These materials are carefully selected not only for their sustainability but also for their ability to meet or exceed performance standards required by elite athletes.

The entire system is designed for long-term use. With a 10+ years lifespan, this longevity-optimized design significantly reduces the need for frequent replacements and the associated environmental toll.

The construction of the Paris Olympic track involved several innovative steps:

Material Sourcing: Collection of waste tires and industrial rubber scraps, followed by refining and grinding into usable granules.

Bio-Based Blending: Integration with natural rubber alternatives to create a performance-grade composite.

High-Temperature Integrated Molding: A breakthrough technique that forms the track surface using high-temperature integrated molding technology, drastically minimizing carbon emissions during production.

Quality Assurance: Each batch is tested for safety, performance, and environmental compliance, then verified by international carbon footprint management systems.

The result is a carbon-neutral certified track that delivers Olympic-grade performance while showcasing environmental responsibility.

Constructing a sustainable prefabricated running track involves a well-coordinated, multi-step process:

Site Preparation: Clear the area, level the ground, and install drainage systems.

Base Layer Installation: Lay a stable, permeable base to support the track system.

Prefabricated Roll-Out: Unroll the prefabricated track sheets, ensuring seamless alignment.

Heat Bonding and Sealing: Use thermal equipment to bond joints and edges, guaranteeing a smooth, trip-free surface.

Line Marking: Apply competition-standard lane markings using eco-friendly, non-toxic paints.

Final Inspection: Perform safety and compliance checks before commissioning.

Huadong’s prefabricated systems significantly reduce installation time and labor. Their closed-loop production system ensures all materials — even production offcuts — are either reused or recycled.

Rigorous testing is crucial to ensure the track meets both safety and performance standards:

Shock Absorption Test: Measures the surface’s ability to cushion impacts and protect joints.

Energy Return Test: Ensures optimal responsiveness and speed potential for athletes.

Traction Test: Evaluates slip resistance under various weather conditions.

Durability Test: Simulates long-term wear to assess how the track holds up over time.

Environmental Compliance: Confirms adherence to carbon footprint guidelines and carbon-neutral certification.

These tests align with World Athletics (formerly IAAF) regulations. Huadong’s lab also includes sustainability metrics, measuring emissions savings and verifying use of recycled materials.

The Olympic movement is embracing sustainability, and sports infrastructure must follow suit. A sustainable prefabricated running track offers numerous benefits:

Environmental Impact: Utilizes waste tires and industrial rubber scraps, reducing landfill waste.

Lower Emissions: The low-carbon manufacturing process and high-temperature integrated molding technology significantly reduce emissions.

Carbon Neutrality: Tracks are carbon-neutral certified, a testament to their eco-credibility.

Material Innovation: By replacing petroleum-based substances with bio-based rubber technology, these tracks reduce reliance on fossil fuels.

Durability and Cost Savings: With a 10+ years lifespan, these tracks require fewer replacements, saving money and reducing waste.

The Paris 2024 Olympic purple track is more than just a colorful curiosity — it’s a powerful statement about the future of sports and sustainability. Crafted from a sustainable prefabricated running track system, it integrates recycled rubber composite materials, a low-carbon manufacturing process, and bio-based rubber technology. Verified by global carbon footprint systems and designed for longevity, the track is a shining example of how the sports world can align with carbon neutrality goals.

As more cities and organizations look to the Olympics for leadership in sustainable innovation, Huadong’s role in delivering this track demonstrates how advanced material science and environmental responsibility can go hand in hand. The purple track is not just a surface to run on — it’s a milestone in building a greener, faster, and more responsible sporting future.