Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

Resurfacing a running track is crucial for maintaining top performance. The cost of resurfacing can vary due to factors like size, material, and repairs. In this article, we’ll explore the cost of running track resurfacing and the key elements that affect pricing. You’ll also learn how to plan your resurfacing project for long-lasting results.

Track resurfacing involves applying a new layer of material over an existing worn-out surface. This differs from complete track reconstruction, which involves removing and rebuilding the entire structure. Resurfacing is a more cost-effective method to restore the track’s functionality without having to start from scratch.

The typical lifespan of a track surface ranges from 7 to 10 years, depending on usage and climate. Signs that indicate the need for resurfacing include cracks, fading markings, and uneven surfaces. Resurfacing ensures that the track remains safe for athletes and retains its performance characteristics.

Resurfacing enhances the track's safety by fixing cracks and restoring traction, thus preventing injuries. It also extends the track’s life, saving money compared to full replacement. A properly resurfaced track also ensures optimal performance for athletes, especially in competitive settings.

Several factors impact resurfacing costs:

● Track size: Larger tracks require more materials and labor, increasing costs.

● Material choice: Polyurethane, rubber, or EPDM surfaces vary in cost, with polyurethane generally being more expensive due to its durability.

● Geographic location: Labor and material costs can differ significantly based on location.

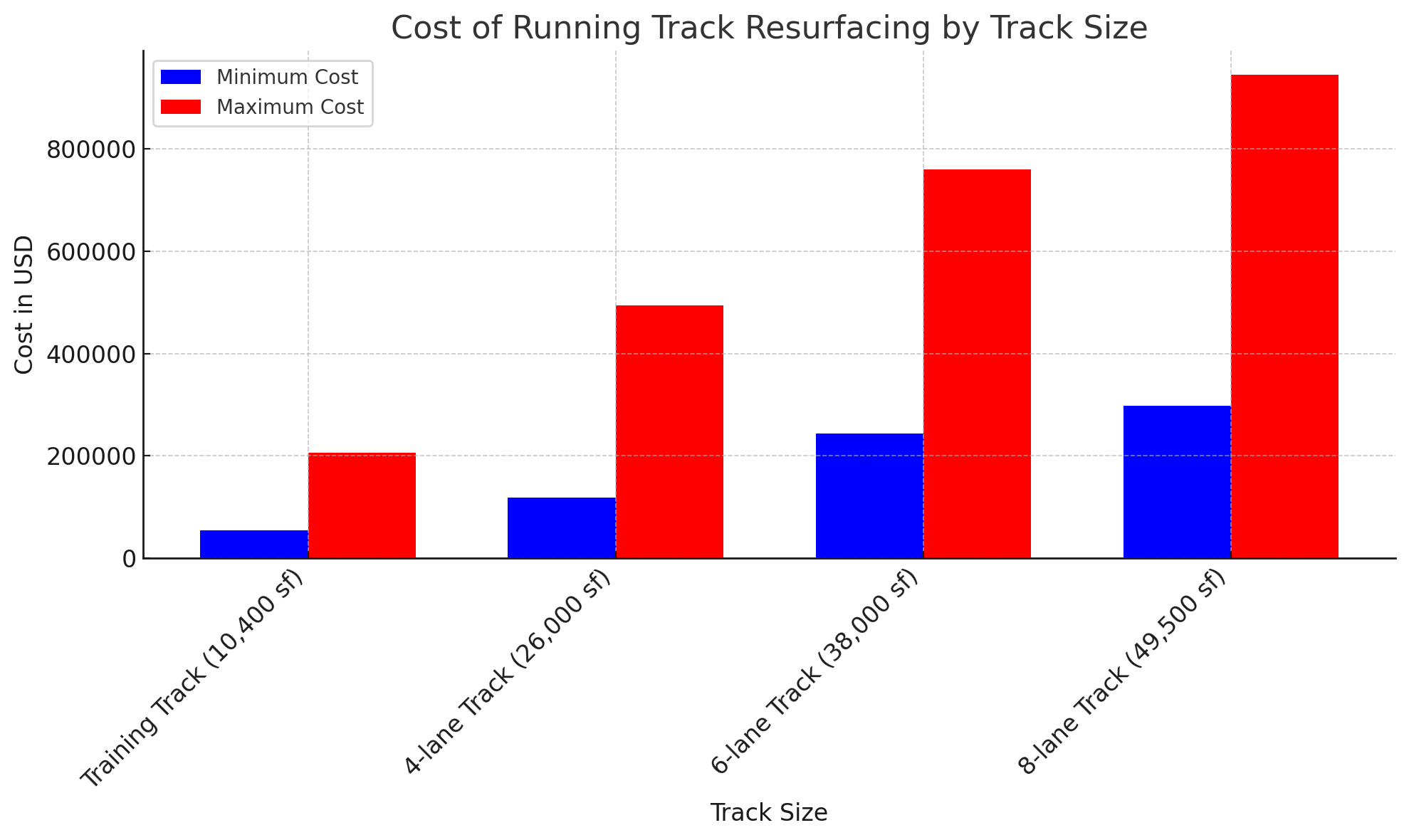

Resurfacing costs depend heavily on track size:

● Training track (10,400 sq. ft): $54,000 – $206,000

● 4-lane track (26,000 sq. ft): $118,000 – $494,000

● 6-lane track (38,000 sq. ft): $244,000 – $760,000

● 8-lane track (49,500 sq. ft): $298,000 – $946,000

These prices can fluctuate based on surface material, labor rates, and additional services required.

Other costs to consider when resurfacing a track:

● Drainage system updates: Essential for preventing water accumulation and preserving the track’s longevity.

● Line marking: Custom track striping to ensure compliance with regulations.

● Disposal of old track surface: Removing and disposing of the old surface adds to the overall cost.

The resurfacing process involves several key stages:

1. Site preparation: Cleaning and clearing the track before applying new material.

2. Removal of the old surface: Stripping the worn-out surface to make way for the new one.

3. Application of new material: Depending on the chosen surface, the new layer is applied and cured.

4. Striping: Marking lanes and other necessary features according to official standards.

Track surfaces vary in cost, durability, and performance:

● Polyurethane: Durable, low maintenance, and suitable for competitive tracks, but more expensive.

● Rubber: Flexible and cost-effective, ideal for recreational and school tracks.

● EPDM: Known for its vibrant color and weather resistance, suitable for outdoor tracks.

Each material has distinct advantages depending on your needs, from performance to budget constraints.

Labor costs can vary depending on the region and the track size. A typical resurfacing project for a standard track may take anywhere from 2 to 4 weeks to complete. Larger tracks and complex projects may require additional time and labor. Proper planning and coordination with a professional contractor can ensure timely completion.

Resurfacing a track not only restores its functionality but also prolongs its use by 7–10 years. This helps avoid the need for costly full-track replacements. The investment in resurfacing is justified by the extended life of the track and the performance benefits for athletes.

Once resurfaced, the track requires less frequent maintenance. The resurfacing process eliminates cracks and uneven surfaces, making it easier to maintain. This leads to long-term savings on repairs, as well as improved safety and performance for athletes.

A cost calculator can help estimate resurfacing expenses based on track size and material selection. It provides a rough estimate, which can be refined further by consulting professionals for a more accurate quote.

Professional contractors assess the track's current condition, provide customized solutions, and ensure that the resurfacing is done to industry standards. Their expertise ensures long-term quality and safety, making them an essential part of the resurfacing process.

While resurfacing can involve significant initial costs, it is far more cost-effective than full track replacement. Resurfacing also saves on long-term maintenance and improves athlete performance, offering good value for money.

For organizations looking to fund resurfacing, grants, loans, and other financing options are available. Securing funding early can help manage the cost effectively and ensure the project proceeds without delays.

Resurfacing a running track is an important investment that enhances safety, performance, and longevity. The costs involved vary depending on track size, surface material, and other factors, but resurfacing provides long-term savings and benefits. For accurate estimates and professional advice, consult experienced resurfacing contractors who can help you plan and execute your resurfacing project effectively. By making the right investment, you can ensure that your track remains a valuable asset for years to come.

Huadongtrack offers expert resurfacing services that guarantee durability and performance. Their high-quality solutions ensure your track delivers optimal results for athletes and facilities.

A: Running track resurfacing involves applying a new layer of material to restore the track's performance and safety. It differs from reconstruction, which is a more extensive process.

A: The cost of running track resurfacing depends on factors like track size, material choice, and labor rates. It typically ranges from $54,000 to $946,000.

A: A track should be resurfaced when wear and tear become significant, causing performance issues or safety concerns. The lifespan of track surfaces varies, but resurfacing is needed every 7-10 years.

A: Key factors include track size, the choice of resurfacing material (e.g., polyurethane or rubber), and labor costs in your region.