Views: 227 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Prefabricated runways, particularly those made of rubber materials for sports use, are increasingly popular due to their durability, ease of installation, and adaptability to different environments. While these structures offer numerous benefits, one common question arises: Can prefabricated runways, especially prefabricated rubber sport runways, be relocated? This article explores this possibility in-depth, examining whether it is practical, cost-effective, and technically feasible to move these structures after installation. By the end of this article, readers will have a comprehensive understanding of the complexities surrounding the relocation of prefabricated runways.

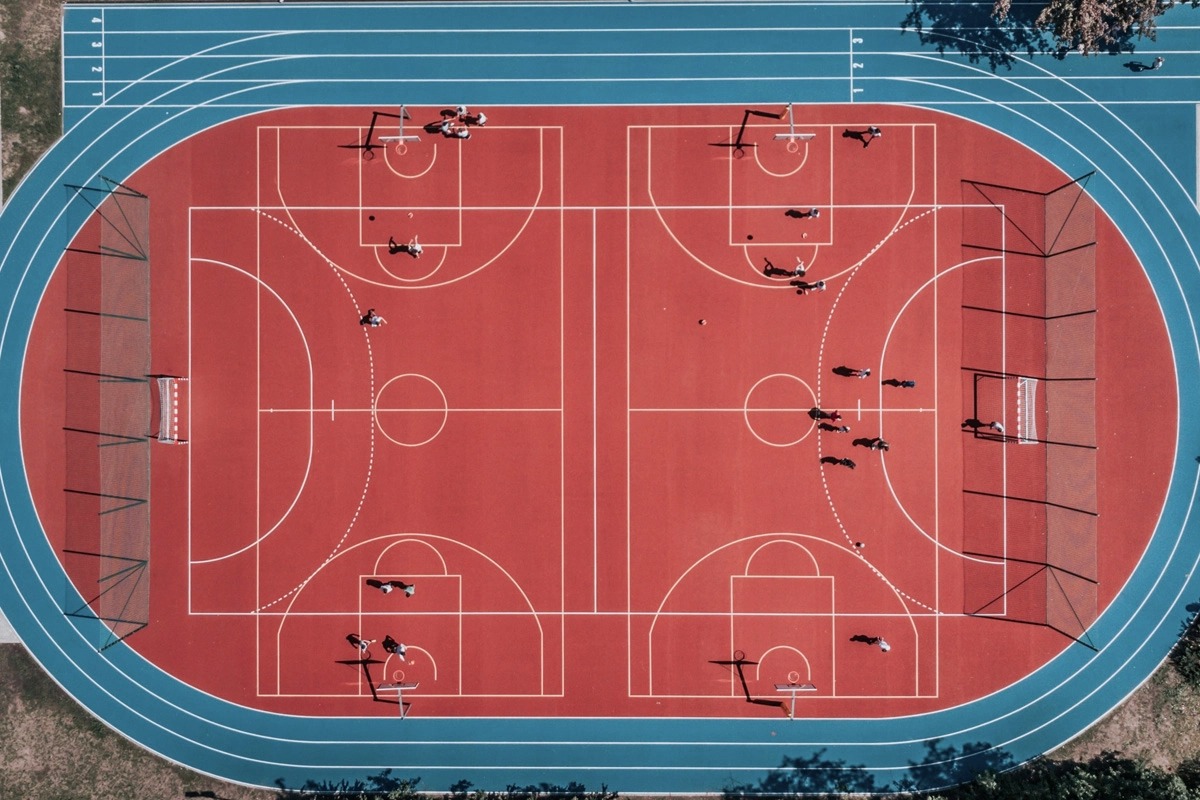

Prefabricated runways are pre-constructed surfaces, typically made from durable materials like rubber, designed for a variety of uses such as sports tracks, airstrips, or temporary facilities. Prefabricated rubber sport runways, specifically, are highly valued in athletic settings due to their impact absorption and traction, which minimize injury risk for athletes.

These runways are assembled off-site and then transported to the location for quick installation, significantly reducing the time required for construction compared to traditional on-site built runways. They are designed to be modular and, in many cases, lightweight, making them an attractive choice for venues that require fast deployment or relocation.

The construction process of a prefabricated runway typically involves multiple layers of material. For rubber sport runways, these layers include a shock-absorbent base, a rubberized top layer for grip, and sometimes additional coatings for protection and durability.

The concept of relocating a prefabricated runway revolves around the idea that these surfaces can be moved from one location to another after initial installation. This idea appeals to several industries and sectors, including sports organizations, temporary event venues, and even military or disaster-relief operations where a quick, adaptable surface is needed.

Relocation is often considered due to changing needs, such as the closure of a sports facility, reorganization of a venue layout, or simply because of seasonal or project-based demands. The relocation of a prefabricated rubber sport runway involves moving the assembled units without significant loss of structural integrity or functionality.

However, while prefabricated materials generally offer flexibility, relocating a full-scale runway—especially a rubber one—presents unique challenges. A thorough understanding of how prefabricated rubber sport runways are designed and installed is essential to evaluating this possibility.

Before diving into the specifics of relocation, it’s important to highlight why prefabricated rubber sport runways are so attractive in the first place. The advantages of these runways go beyond ease of installation, making them a popular choice for many sports facilities.

Prefabricated rubber sport runways are designed to endure heavy use and harsh weather conditions. The materials used are resistant to UV rays, moisture, and temperature fluctuations, ensuring a long service life. This durability is essential, especially for outdoor sports facilities.

Compared to traditional on-site construction, prefabricated runways are more affordable to install. The modular design reduces labor costs and speeds up installation, providing significant cost savings, especially for temporary or short-term projects.

Rubberized surfaces, when sourced from recycled materials, can be an eco-friendly alternative to traditional asphalt or synthetic materials. This makes them attractive for projects that are sensitive to environmental impact.

Athletes benefit from the shock-absorbing properties of rubber, which reduces the likelihood of injury during use. This is particularly important in track and field events where speed and high-impact movements are common.

The feasibility of relocating prefabricated rubber sport runways depends on several factors, including the type of materials used, the method of installation, and the location of the runway.

Rubber sport runways are often designed with modular, interlocking tiles or rolls. These individual units make relocation more plausible, as they can be disassembled, transported, and reassembled in a different location. However, the design of the interlocking system must be considered to ensure that disassembly doesn’t compromise the structural integrity of the runway.

The manner in which the runway is installed plays a crucial role in its ability to be relocated. If the runway is glued down or secured with adhesives, it becomes much more difficult and time-consuming to remove. However, if the runway is loosely laid with minimal ground preparation, it is easier to lift and transport.

Relocation is also affected by the infrastructure of the new site. The ground must be level and stable enough to support the prefabricated runway, and additional work may be required to prepare the area for the new installation.

While the idea of relocating prefabricated rubber sport runways is appealing, several challenges can make the process difficult or expensive. These challenges include:

When a runway is relocated, the individual components may experience wear and tear during transportation or disassembly. Over time, the integrity of the materials could be compromised, especially if the runway has been used extensively.

Relocation is not always as cost-effective as the initial installation. Moving a large, heavy structure involves significant labor, equipment, and potential reinstallation fees. The cost of moving and reassembling a prefabricated rubber sport runway can sometimes exceed the cost of building a new one.

Though prefabricated runways are often more eco-friendly than traditional materials, the environmental impact of relocating them is still significant. The transportation of large, bulky materials can contribute to carbon emissions, and the physical wear on the materials may lead to increased waste.

Relocating a prefabricated rubber sport runway is a multi-step process that requires careful planning and execution. The following steps outline the typical procedure for relocation:

Before relocating the runway, the new site must be prepared. This includes leveling the ground, ensuring proper drainage, and assessing any environmental factors that may affect the installation.

The runway must be carefully disassembled, with each section removed in a way that prevents damage. If the sections are modular and interlocking, they should be carefully labeled to facilitate reassembly.

Once disassembled, the runway sections are transported to the new site. This step involves securing the materials for safe transit, using trucks or other heavy machinery if necessary.

The prefabricated rubber sport runway is reassembled at the new location. This step may involve resetting the interlocking tiles or rolls, ensuring they are properly aligned and level.

When deciding whether to relocate a prefabricated rubber sport runway, it is essential to consider both environmental and economic factors.

The production of rubber materials used in these runways may have a significant environmental impact, especially if the materials are not sourced sustainably. Additionally, relocating large sections of material can increase the carbon footprint of the project due to transportation and energy use.

From an economic standpoint, relocating a prefabricated runway may not always be the most cost-effective solution. Factors such as transportation costs, reinstallation fees, and potential damage to materials must be considered. In some cases, building a new runway may be more economical than relocating an old one.

Relocating a prefabricated rubber sport runway is technically feasible but presents a series of challenges that must be carefully considered. While these runways offer numerous advantages in terms of cost, speed of installation, and durability, their relocation is not always a straightforward process. The factors involved, including material integrity, installation methods, labor costs, and environmental impact, all play a role in determining whether relocation is a viable option.

For organizations considering relocating a prefabricated runway, the decision should be based on a detailed analysis of these factors to ensure that the process is cost-effective and environmentally sustainable. In many cases, building a new runway may be more practical than relocating an old one.

1. Can a prefabricated rubber sport runway be moved more than once?

Yes, but the more frequently it is moved, the greater the risk of wear and tear on the materials. Additionally, each relocation incurs additional labor and transportation costs, making it less economical over time.

2. How long do prefabricated rubber sport runways last?

With proper maintenance, prefabricated rubber sport runways can last up to 15-20 years, depending on usage and environmental conditions.

3. What are the main benefits of using prefabricated rubber for sport runways?

The primary benefits include durability, cost efficiency, impact absorption, and ease of installation. Rubber surfaces are also eco-friendly when made from recycled materials.