Views: 228 Author: Site Editor Publish Time: 2026-01-31 Origin: Site

Installing a prefabricated rubber sport runway is a highly efficient way to enhance athletic facilities, providing athletes with a safe, durable, and high-performance track surface. Prefabricated rubber sport runways are increasingly popular due to their ability to deliver fast, cost-effective installations with minimal disruption. Unlike traditional poured-in-place tracks, these runways come in interlocking segments, making the installation process simpler and faster.

Whether you're installing a runway for professional sports, schools, or recreational use, it's important to follow the correct procedures to ensure optimal performance and longevity of the track. In this article, we will break down the steps involved in installing a prefabricated rubber sport runway and discuss key considerations to ensure success.

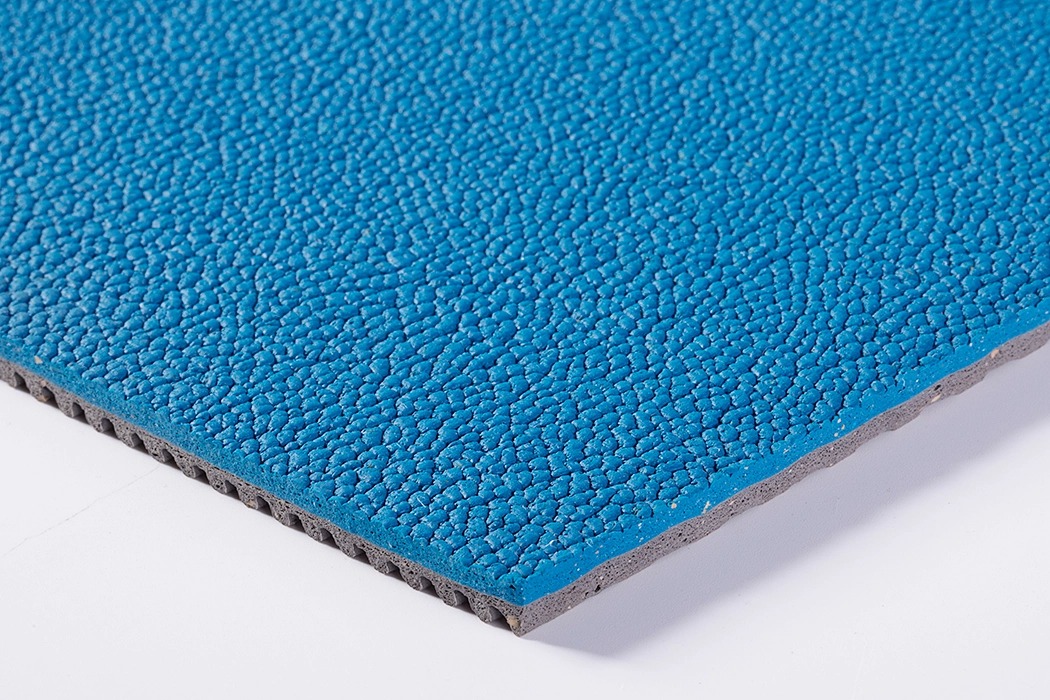

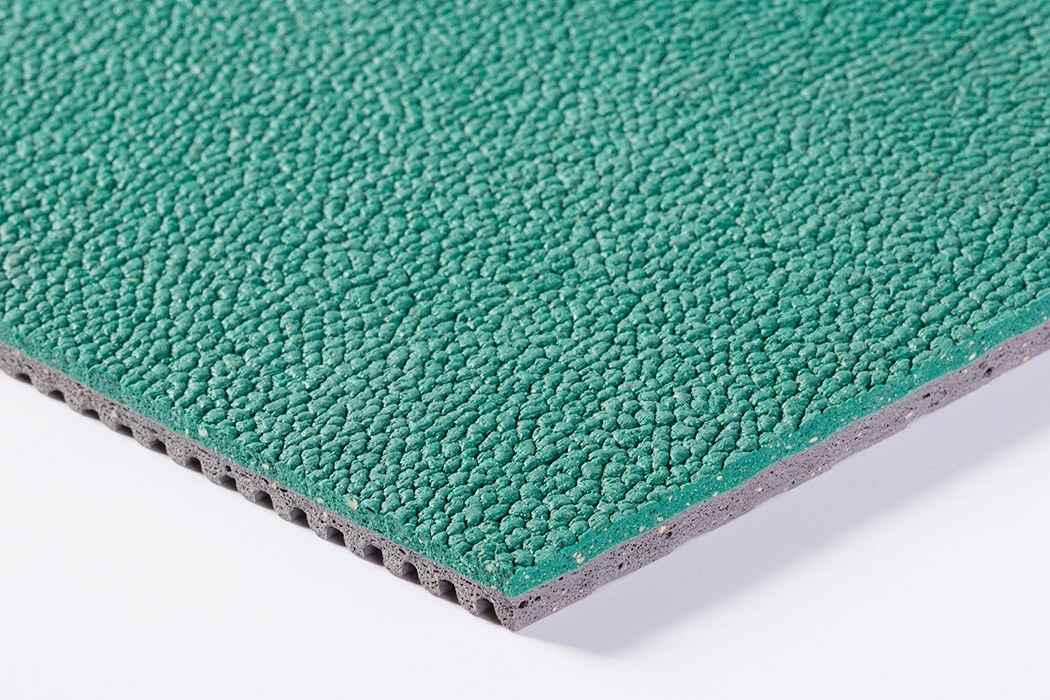

Prefabricated rubber sport runways are modular systems designed for ease of installation and durability. They consist of pre-manufactured rubber tiles or sections that interlock to form a seamless surface. These runways are made from a mix of synthetic rubber compounds, which offer superior traction, shock absorption, and weather resistance compared to traditional asphalt or concrete surfaces.

The key advantages of using prefabricated rubber sport runways include:

Quick Installation: Prefabricated tiles are easier and faster to install compared to traditional surfacing methods.

Durability: These runways are highly resistant to wear and tear, making them ideal for high-traffic areas.

Safety: The rubber surface reduces the risk of injury, providing cushioning that protects athletes during their performance.

Cost-Effectiveness: The modular nature of these runways reduces labor costs and installation time.

However, the quality and durability of the installation are highly dependent on the preparation and execution of the installation process.

Before starting the installation process, it’s essential to ensure that you have the right tools and materials. Below are some key considerations:

Choosing the right site is critical for the long-term performance of your prefabricated rubber sport runway. The surface should be stable, dry, and level. If you're installing the runway outdoors, ensure that there is proper drainage to prevent water accumulation underneath the tiles, which could lead to damage or instability over time.

To install a prefabricated rubber sport runway, you will need the following tools and equipment:

| Tool/Equipment | Purpose |

|---|---|

| Rubber mallet | For gently tapping tiles into place without damaging them |

| Measuring tape | To ensure precise measurements during installation |

| Level | To check for evenness of the surface |

| Knife or utility blade | For trimming edges of the rubber tiles if necessary |

| Adhesive (optional) | To secure tiles in place for additional stability |

| Hand gloves | To protect your hands during the installation process |

| Safety goggles | To protect your eyes from debris during cutting or trimming |

Once the prefabricated rubber tiles arrive, inspect the materials to ensure they are free from defects or damage. Look for any cracks or warping that could affect the installation process. Verify that the tiles are the correct size and quantity for your project.

Proper site preparation is the foundation of a successful installation. The surface beneath the runway must be smooth and even to ensure that the rubber tiles fit snugly together. Any unevenness can result in gaps or instability, which can lead to a deterioration of the runway's performance over time.

Step 1: Clear the Area – Remove any debris, dirt, or vegetation from the area where the runway will be installed. If there are large rocks or tree roots, dig them out.

Step 2: Level the Ground – Use a level to ensure the surface is flat. For larger installations, consider using a compacted base layer like crushed stone or gravel to provide added stability and drainage.

Once the site is ready, unpack the prefabricated rubber tiles and inspect each piece. Ensure that the interlocking edges are in good condition and that you have all the necessary tiles to complete the installation. Organize the tiles by type, size, or color for a smoother installation process.

Before laying the rubber tiles, it’s important to lay down a proper foundation to support the prefabricated runway. If installing outdoors, you may want to consider adding a layer of gravel or a geotextile fabric to prevent weed growth and improve drainage.

Step 1: Create a Border – Mark the perimeter of the runway using stakes and string. This will serve as a guide to keep the tiles aligned.

Step 2: Apply Adhesive (Optional) – While most prefabricated rubber runways rely on the interlocking system to hold the tiles in place, some installations may benefit from using adhesive between the tiles for extra stability, especially in high-traffic areas.

Now comes the process of assembling the tiles. Start by laying the first tile at one corner of the designated area. Use a rubber mallet to gently tap the tiles into place, ensuring that the interlocking edges are securely connected.

Step 1: Align the Tiles – Continue laying tiles row by row, ensuring that each tile is aligned correctly with the previous one. Take care to avoid stretching or misaligning the tiles, as this can lead to uneven seams.

Step 2: Trim Excess Edges (if needed) – If the tiles need to be trimmed to fit around corners or curves, use a utility knife to carefully cut them to size.

Once all the tiles are laid, make a final check to ensure everything is level and securely connected. If necessary, apply additional adhesive or fasteners to hold the edges in place.

Cost-Effective Installation: The modular nature of the tiles reduces labor and material costs, making the installation process more affordable than traditional poured-in-place surfaces.

Customization: Prefabricated rubber runways can be customized in terms of color, texture, and size to meet specific needs or aesthetic preferences.

Low Maintenance: These runways are easy to maintain, requiring only periodic cleaning and occasional repairs to ensure longevity.

Versatility: Whether used for professional sports, schools, or recreational spaces, these runways can be installed in a wide range of environments.

Neglecting Site Preparation: A poorly prepared base can lead to an uneven or unstable surface, which will affect the performance of the runway.

Overlooking the Drainage System: Without proper drainage, water can pool underneath the tiles, causing them to shift or deteriorate.

Improper Tile Alignment: Misaligned tiles can lead to gaps or uneven surfaces, which can cause tripping hazards or damage to the runway over time.

Skipping Safety Precautions: Always wear gloves and safety goggles when handling the tiles to prevent injury.

To ensure that your prefabricated rubber sport runway remains in top condition, regular maintenance is essential. Some key tips include:

Regular Cleaning: Sweep or wash the surface regularly to remove debris and dirt.

Inspect for Damage: Check for any signs of wear or damage, especially in high-traffic areas. Replace any damaged tiles promptly to avoid further issues.

Reapply Adhesive: If you notice that tiles are loosening, consider reapplying adhesive to keep them securely in place.

Installing a prefabricated rubber sport runway is a straightforward process when done correctly. By following the necessary steps for site preparation, material inspection, and tile assembly, you can achieve a durable and high-performance surface that will serve athletes for years to come. This type of runway is an excellent investment for anyone looking to build or upgrade their athletic facilities efficiently.

Q: How long does it take to install a prefabricated rubber sport runway?

A: Depending on the size of the project and the experience of the installers, the installation process can take anywhere from a few days to a week.

Q: Can prefabricated rubber sport runways be installed over an existing surface?

A: Yes, prefabricated rubber tiles can be installed over an existing surface, provided the base is stable and level.

Q: Do I need professional help to install a prefabricated rubber sport runway?

A: While the installation process is relatively simple, it may be beneficial to hire professionals for larger projects to ensure everything is done correctly and efficiently.

Q: How do I maintain my prefabricated rubber sport runway?

A: Regular cleaning, inspection for damage, and occasional reapplication of adhesive or repairs are essential for maintaining the runway's condition.

content is empty!