Views: 0 Author: Site Editor Publish Time: 2025-07-08 Origin: Site

When you want a new sports facility, running track installation companies help bring your vision to life. These experts design, build, and maintain tracks that keep athletes safe and boost performance. You get access to skilled teams who know which materials last the longest and which layouts work best. Think about your budget, the quality of materials, and how the company supports you after the track is built. Your choice matters for years to come.

Running track installation companies handle everything from site assessment to design, material selection, installation, and maintenance to build safe and durable tracks.

Choose a company with strong experience, a good portfolio, quality materials, solid warranties, and clear communication to ensure your project succeeds.

A clear timeline and regular updates keep your project on schedule and help avoid surprises during installation.

Regular maintenance like sweeping, cleaning spills, and checking for damage helps your track last longer and stay safe.

Ask about maintenance plans and warranties to protect your investment and get support after installation.

When you start a running track project, you want a team that covers every step. Running track installation companies offer a full range of services to make sure your track is safe, durable, and ready for action. Let’s break down what you can expect from these experts.

You need a solid plan before any work begins. The company will visit your site to check the land, measure the area, and look for any challenges. They might talk to coaches, athletes, and school staff to learn what you need. Sometimes, they use surveys, interviews, and even photos or videos to get a clear picture. This helps them spot problems early and find the best spot for your track.

Stakeholder interviews and focus groups help gather feedback.

Field visits and observations give real-time insights.

Mixed methods, like combining surveys and photos, make the assessment stronger.

Once the site is ready, the design phase starts. You work with the company to choose the track shape, number of lanes, and special features. They create a timeline and set clear goals for the project. Good planning means fewer surprises later. Companies use tools like us, Huadong Sports Track to track progress and keep everything on schedule. They also test surfaces at each stage to meet safety standards.

Choosing the right materials is key. You want a track that lasts and feels good to run on. Companies like GeoSurfaces and Hellas Construction offer different surfaces for all levels, from local schools to pro stadiums. Advanced products, such as the Huadong Track Prefabricated Runway, give you options for durability and performance.

Now the real work begins. The team prepares the ground, lays the base, and installs the track surface. They follow strict steps to make sure everything lines up and meets quality checks. Scheduling is important, so they try to finish on time and avoid disrupting other activities.

Your track needs care to stay in top shape. Many companies offer cleaning, repairs, and regular check-ups. This keeps your track safe and looking great for years. With the right support, you can fix small issues before they become big problems.

Tip: Ask about maintenance plans when you choose your provider. It can save you money and headaches down the road.

Picking the right team for your running track project can feel like a big job. You want a company that delivers quality, keeps you informed, and stands by their work. Here’s how you can make a smart choice.

Start by looking at how long the company has been in business. Companies with years of experience, like American Athletic Track and Turf or Byrne and Jones, have seen many types of projects. They know how to handle surprises and keep things on track. When you choose a company with a solid reputation, you lower your risk. You get a team that understands safety rules and meets deadlines. Owners often pick contractors who have a proven track record and strong credentials. This helps you feel confident that your project will finish on time and meet your needs.

Ask to see past projects. A good company will show you photos, videos, or even let you visit a finished track. Look for projects that match your goals. Maybe you want a high school track, a college facility, or a community space. Seeing real examples helps you judge their skills. Companies like SIS Pitches often highlight their best work to show what they can do. When you review a company’s portfolio, you see their quality and style. You also learn if they have handled projects like yours before.

Tip: Talk to past clients if you can. Ask about their experience and if the company met their expectations.

Not all tracks use the same materials. Some surfaces last longer or feel better underfoot. Ask what products the company uses. Many running track installation companies offer advanced options, such as the Huadong Track Prefabricated Runway, which gives you a strong and reliable surface. Compare the technology and materials each company offers. This helps you pick a track that fits your budget and performance needs.

Here’s a quick table to help you compare:

| Material Type | Durability | Comfort | Typical Use |

|---|---|---|---|

| Polyurethane | High | Good | Schools, stadiums |

| Prefabricated Runway | Very High | Great | Pro, multi-purpose |

| Latex | Medium | Fair | Budget projects |

A good warranty shows that the company stands by its work. Ask what is covered and for how long. Some companies offer warranties on both materials and labor. This means if something goes wrong, you have support. Compare warranty terms from different running track installation companies. Longer and more complete warranties can save you money and stress later.

Cost matters, but it’s not the only thing to think about. Prices for running tracks can range from $50,000 for a basic track to over $1 million for a top-level facility with extra features. Get detailed quotes from a few companies. Make sure you know what is included in the price. Sometimes a lower price means fewer services or cheaper materials. Look for value, not just the lowest number.

Ask for a breakdown of costs.

Check if maintenance or aftercare is included.

Compare what you get for your money.

Choosing the right company takes time, but it pays off. When you look at experience, review portfolios, compare materials, check warranties, and understand costs, you set your project up for success.

You want your running track ready on time. Most projects follow a clear step-by-step plan. First, the team prepares the site and checks the ground. Next, they lay the base and install the track surface. Each step has its own schedule. A basic track might take a few weeks, while a bigger project could last a few months. Good companies share a timeline with you at the start. They update you if anything changes, so you always know what to expect.

Clear communication keeps your project on track. You should get quick replies to your questions. Contractors who answer fast help avoid delays. Good teams use regular updates, online portals, and even surveys to keep you in the loop. They listen to your feedback and fix problems quickly. Here are some ways companies measure communication:

Prompt replies from contractors

Clear messages to avoid mistakes

Willingness to listen and act on your feedback

Client satisfaction scores after the project

Tools like surveys and online updates

Most companies ask you to rate their work at the end. These scores help them improve and make sure you feel heard.

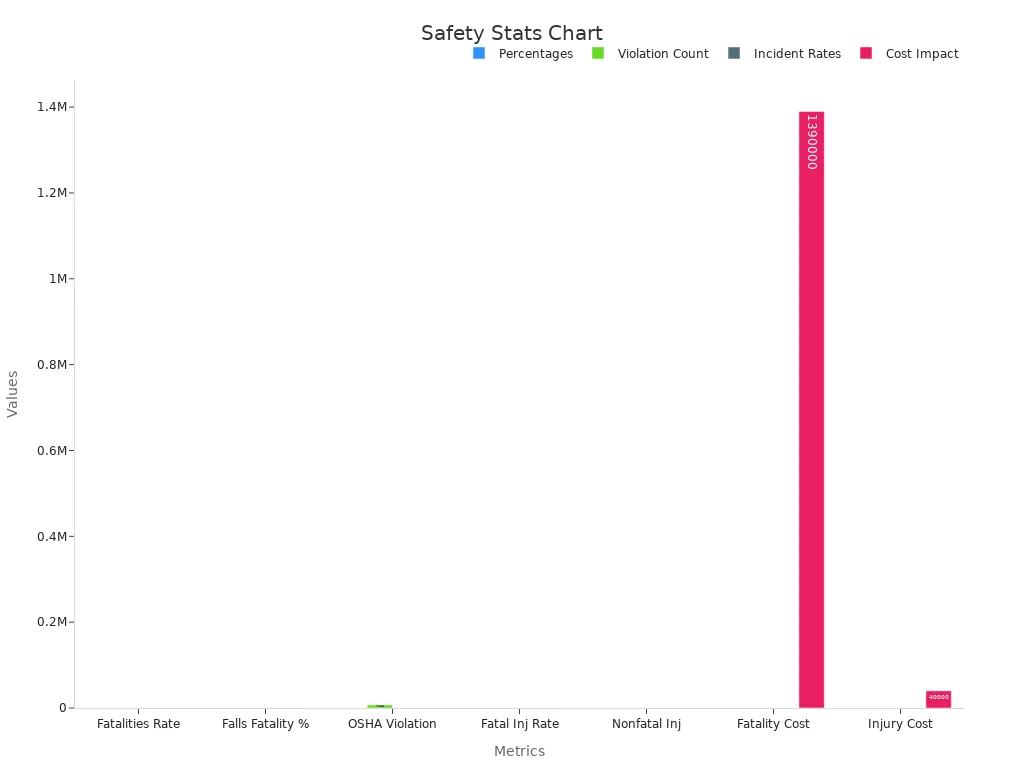

Safety matters every day on a construction site. Workers use special gear and follow strict rules to stay safe. Falls and trips are the biggest risks, so teams get extra training and use the right equipment. Companies follow OSHA rules and run safety checks often. They also use new tech like smart helmets and VR training to spot dangers early.

| Aspect | Evidence Supporting Safety Practices |

|---|---|

| Workplace Fatalities in Construction | Construction accounts for about 20% of all workplace fatalities in 2023, highlighting the high-risk nature of the industry and the critical need for safety compliance. |

| Leading Cause of Fatalities | Falls and trips cause 38.4% of construction deaths, emphasizing the importance of fall protection training and equipment. |

| OSHA Violations | The most cited OSHA violation in 2023 was lack of fall protection, with 7,188 violations reported, underscoring the focus on compliance to reduce incidents. |

| Incident Rates | Fatal injury rate is 9.6 per 100,000 workers; nonfatal injuries occur at 2.3 per 100 full-time workers, showing the frequency of incidents without proper safety measures. |

| Cost Impact | Average cost per fatality is $1,390,000; injuries cost about $40,000 each, demonstrating the financial incentive for strict safety adherence. |

| Proven Safety Practices | Adherence to OSHA regulations, comprehensive safety training (including fall protection, electrical safety), regular safety audits, and use of advanced technologies (VR training, automated monitoring) reduce accidents and improve compliance. |

| Safety Culture | Leadership commitment, open communication, safety incentive programs, and worker participation foster a safety-first culture that supports incident reduction. |

| Technology Use | VR and AR training, smart helmets, and real-time monitoring enhance hazard awareness and training effectiveness, contributing to safer project execution. |

You want your track to last and perform well. Quality control means checking every step, from the ground up. Teams test the surface, measure the lines, and inspect the whole track before you use it. If they find a problem, they fix it right away. This careful process gives you a safe, smooth, and long-lasting running track.

You want your running track to look great and last for years. Regular care makes a big difference. Start by sweeping the surface every week. This keeps dirt, leaves, and small rocks from building up. If you see any spills or stains, clean them right away with water and a mild soap. Avoid using harsh chemicals. They can damage the track.

Check the track after storms or heavy use. Look for puddles or soft spots. If you spot any, let your maintenance team know. You can also set up a simple schedule to inspect the track each month. Write down anything you notice. This helps you catch problems early.

Tip: Keep heavy equipment and sharp objects off the track. This prevents cuts and dents.

Even with good care, some problems can pop up. You might see cracks, fading, or loose edges over time. Sometimes weeds try to grow along the sides. Water can collect in low spots if the drainage is not perfect. If you notice any of these issues, act fast. Small repairs cost less and keep your track safe.

Here’s a quick table of common issues and what you can do:

| Issue | What to Do |

|---|---|

| Cracks | Call for repairs |

| Fading Color | Ask about resurfacing |

| Loose Edges | Secure or patch quickly |

| Weeds | Remove and treat edges |

| Water Pools | Check drainage, report |

You don’t have to handle everything alone. Many running track installation companies offer ongoing support and repair services. You can call them for regular check-ups, deep cleaning, or big repairs. Some companies even give you a maintenance plan when they build your track. This plan tells you what to do each season. If you ever have questions, reach out to your provider. They want your track to stay safe and ready for action.

You want the best for your sports facility, so take these steps when picking running track installation companies:

Check the quality of information from each company.

Set clear goals and use key performance indicators to compare options.

Use a standard checklist to review every provider.

Visit sites and talk with vendors to see their work up close.

Ask for quotes or a site assessment before you decide. Quality, experience, and good support make all the difference.

Most running tracks take four to twelve weeks to finish. The timeline depends on weather, site conditions, and track size. Your company will give you a schedule before work starts.

You can pick from polyurethane, latex, or prefabricated surfaces. Each type has different benefits. Ask your installer which one fits your needs best.

Sweep the track often. Clean up spills right away. Check for cracks or damage every month. If you see a problem, call your installer for help.

Yes, you can use your track in most seasons. Avoid using it during heavy snow or ice. Always check the surface before running after storms.

Most companies offer warranties on both materials and labor. Always ask for details. A good warranty gives you peace of mind.