Views: 0 Author: Site Editor Publish Time: 2025-07-22 Origin: Site

You can expect running track resurfacing in 2025 to range from $54,000 to $946,000, depending on the size and condition of your facility. The main factors that influence cost include track size, surface material, location, and labor. Regular running track resurfacing improves safety, keeps athletes performing well, and helps your track last longer.

Here is a quick look at resurfacing costs for different track sizes in 2025:

| Track Size | Resurfacing Cost Range (2025) |

|---|---|

| Training track | $54,000 – $206,000 |

| 4-lane track | $118,000 – $494,000 |

| 6-lane track | $244,000 – $760,000 |

| 8-lane track | $298,000 – $946,000 |

Running track resurfacing costs vary widely, from about $54,000 to nearly $1 million, depending on track size, materials, and condition.

Choosing high-quality materials like polyurethane increases upfront costs but extends track life and reduces maintenance.

The resurfacing process includes assessment, surface preparation, applying new layers, and careful curing to ensure durability and safety.

Regular cleaning and prompt repairs help maintain your track, prevent damage, and extend its lifespan.

Select experienced resurfacing companies that use quality materials, communicate clearly, and provide warranties for the best results.

You will see a wide range of resurfacing costs for running tracks in 2025. Most projects fall between $54,000 and $946,000. The typical 8-lane track costs between $400,000 and $800,000 to resurface or rebuild, depending on the materials and features you choose. Some basic latex systems start around $50,000, but high-end polyurethane or full replacement projects can reach $1 million. Synthetic tracks cost more at first, but they last longer and need less maintenance over time.

Tip: Investing in a higher quality surface, such as polyurethane, often means your track will last 15 to 20 years or more with minimal repairs. For example, Franklin & Marshall College’s polyurethane track lasted over 20 years.

Here is a breakdown of common running track resurfacing options and their costs:

| Cost Category | Cost Range (USD) | Notes |

|---|---|---|

| Structural Spray Resurfacing | Around $90,000 | Includes minor crack repairs |

| Base Mat or Surfacing System Replacement | $160,000 - $170,000 | Assumes good condition of asphalt base |

| New Track Construction | $600,000 - $700,000 | Full base replacement and new system |

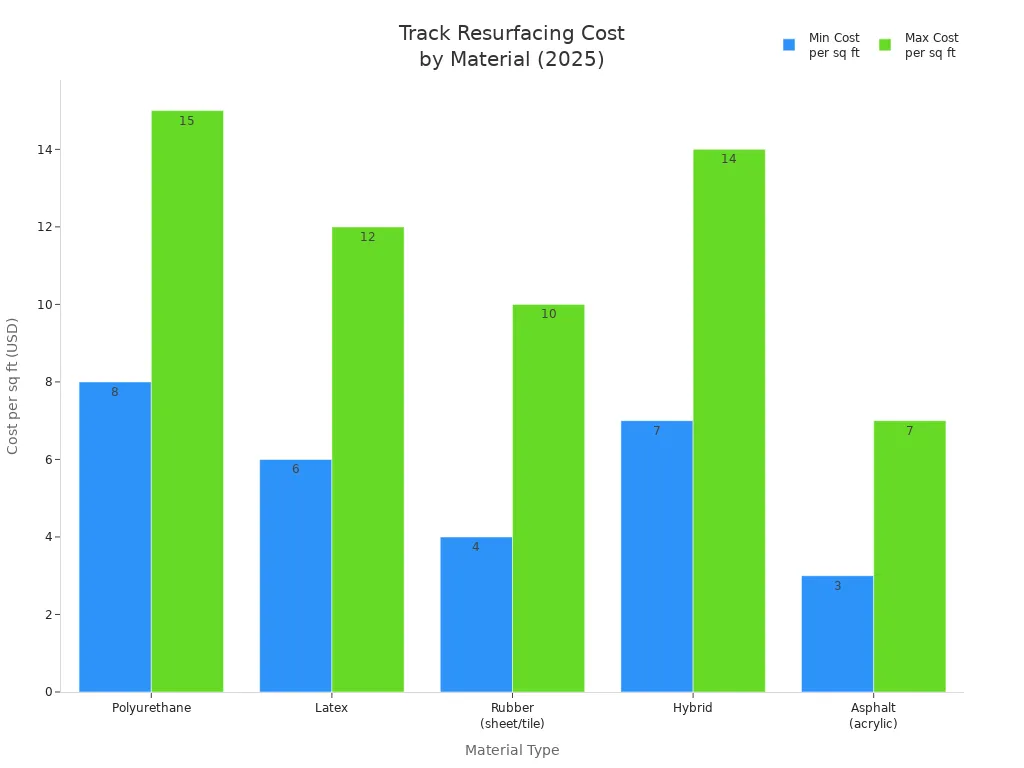

Material choice has a big impact on your upfront cost estimates. The table below shows how much you might pay per square foot for different surfaces:

| Material Type | Cost per sq ft (USD) | Notes |

|---|---|---|

| Polyurethane | $8–$15+ | Most expensive, high performance |

| Latex | $6–$12 | Lower cost, shorter lifespan |

| Rubber (sheet/tile) | $4–$10 | Moderate cost |

| Hybrid | $7–$14 | Mix of materials |

| Asphalt (acrylic) | $3–$7 | Cheapest, least durable |

Several factors influence resurfacing costs. You need to consider each one before starting your project:

Material Type and Quality

The surface material you choose, such as latex, polyurethane, or hybrid, affects both the price and the lifespan of your track. Polyurethane costs more but lasts longer and needs less maintenance. Latex is cheaper but requires more frequent repairs.

Track Size and Lane Width

Larger tracks and more lanes mean higher costs. Pricing is usually per square foot, so an 8-lane track will cost much more than a 4-lane track.

Site Preparation and Base Condition

The condition of the asphalt base is critical. If the base has cracks or damage, you may need repairs or a full replacement, which increases costs. Proper drainage and leveling are also important for durability.

Labor Costs and Location

Labor rates vary by region. Projects in urban areas or regions with higher wages will cost more. Local market conditions and business practices also play a role.

Additional Features and Equipment

Lane markings, lighting, fencing, and athletic equipment add to the total cost. You should also budget for contingency funds to cover unexpected expenses.

Regulatory Requirements and Timing

Permits, planning approvals, and inflation can affect your final price. Delays or changes during the project may increase costs.

Note: Always get a professional assessment of your site before you begin. This helps you avoid surprises and ensures your running track resurfacing project stays on budget.

Running track resurfacing in 2025 follows a clear, step-by-step process. You can expect the entire project to take between 2 and 8 weeks, depending on the size and condition of your track. The process includes assessment, surface preparation, new surface application, and final curing and inspection. Polyurethane and rubberized surfaces remain the most popular choices in 2025 because they offer durability, safety, and excellent performance for athletes.

You start the process with a thorough assessment of your track. Professionals check for cracks, bubbles, fading, and uneven spots. They also test the surface for hardness, evenness, and friction to make sure it meets safety and performance standards. This step helps you decide if you need repairs or a full resurfacing.

Tip: Always ask for a professional evaluation. Experts use tools to measure surface hardness and evenness, and they follow standards set by groups like World Athletics and ASTM. This ensures your track will be safe and ready for competition.

During planning, you choose the right materials for your needs. Polyurethane is the top choice in 2025 for its long life and weather resistance. Rubberized surfaces and EPDM also provide great traction and shock absorption. You also need to consider drainage, lane layout, and any extra features like steeplechase barriers or jump runways.

Surface preparation is a critical part of the running track resurfacing process. You need to make sure the base is clean, smooth, and ready for the new surface. Here’s how this stage usually goes:

Cleaning: Workers use power washers and scrapers to remove dirt, debris, and loose granules.

Minor Repairs: They seal cracks, patch holes, and fix any damaged spots. For larger issues, they may mill or repave sections of the asphalt base.

Drainage Check: Proper drainage prevents water damage. Crews inspect and fix any drainage problems before moving forward.

Priming: After cleaning and repairs, they apply a special primer to help the new surface stick to the base.

Protection: Workers protect nearby areas with plastic or fencing to prevent overspray during application.

Note: A smooth, level base is essential. Crews use straightedges and rollers to keep the surface within strict tolerances and maintain a 1% pitch for drainage.

Once the base is ready, you move to the new surface application. This step uses advanced materials and equipment to create a durable, high-performance track.

Material Selection: Most tracks in 2025 use polyurethane, rubberized systems, or EPDM. Polyurethane offers the best durability and shock absorption. Rubberized surfaces, often made from recycled materials, provide excellent traction and comfort.

Layering: Crews apply several layers. First, they spread rubber granules mixed with a polyurethane binder. Then, they spray more binder and repeat the process to build up the surface, usually to about 3/8 inch thick.

Customization: You can choose colors and textures to match your school or facility’s needs. Some tracks use UV-protective coatings for extra durability.

| Surface Material | Advantages | Disadvantages |

|---|---|---|

| Polyurethane | Long-lasting, weather-resistant, safe | Higher upfront cost |

| Rubberized (Recycled) | Sustainable, elastic, good traction | May tear if rubber quality is low |

| EPDM | UV resistant, shock absorbent | Less common for competition tracks |

| Latex Bound | Cost-effective, customizable | Less durable than polyurethane/EPDM |

Callout: Polyurethane and rubberized surfaces dominate the market in 2025. They provide the best mix of safety, comfort, and low maintenance.

After the new surface goes down, you need to let it cure. Curing times depend on the material and weather, but usually take several days. This step is important for strength and durability.

Curing: The surface must stay undisturbed while it hardens. Temperature and humidity can affect curing time.

Marking: Once cured, crews paint lane lines, start and finish marks, and event markings to meet official standards.

Inspection: Professionals inspect the finished track for quality. They check for evenness, proper markings, and surface integrity. Regular tests ensure the track meets safety and performance requirements.

Reminder: Never rush the curing process. Proper curing ensures your track lasts for years and performs at its best.

By following each step carefully, you ensure your running track resurfacing project delivers a safe, high-quality surface that meets modern standards.

You can often solve minor issues with running track repair. Small, localized damage does not always mean you need a full resurfacing. Look for these signs to decide if repair is the right choice:

Minor cracks or small holes in the surface

Hairline splits that have not spread across large areas

Loss of traction or a slick feel, especially when the track is wet

Puddling or uneven spots caused by drainage issues

Early signs of wear that do not expose the base material

If you catch these problems early, running track repair can extend the life of your surface and keep it safe for athletes.

Sometimes, damage goes beyond what running track repair can fix. You should consider resurfacing when you see:

Widespread or deep cracking that patching cannot solve

Rust stains or surface failure from poor subbase materials

Low spots that cause water to pool, showing drainage or foundation problems

Heavy wear on inside lanes that affects the track’s performance

Damage from improper construction or incompatible materials

Exposed base materials like asphalt showing through the surface

Resurfacing gives your track a fresh start and restores safety and performance for everyone who uses it.

A professional evaluation helps you make the right choice between repair and resurfacing. Experts inspect your track for cracks, bubbles, thinning rubber, drainage issues, and layer separation. They consider how you use the track—whether for competition or recreation—and check the type of surface you have. Professionals also look at your budget and how much time you can allow for repairs. Their experience ensures you get the best advice for your facility’s needs and athlete safety.

Selecting the right track resurfacing company is one of the most important steps for a successful project. You want a partner who delivers quality, safety, and long-lasting results. Here’s how you can make a smart choice.

Look for a track resurfacing company with a proven track record. Companies with extensive experience and a strong portfolio of similar projects can handle both outdoor and indoor tracks. For example, Replay Surfacing Inc. transformed Dasher Park in 2025 with a vibrant, durable running track. NovoTrack has completed over 100 athletic track projects worldwide, showing their expertise in resurfacing and installation. When you review a company, check for:

Completed projects similar to your facility

Positive client reviews and testimonials

Proper licensing, bonding, and insurance

Maintenance and inspection services after resurfacing

Tip: Ask for photos or case studies of past projects to see the quality of their work.

A reputable track resurfacing company uses high-quality materials and advanced methods. You should expect them to offer options like polyurethane, latex, EPDM, and synthetic blends. These materials provide durability and weather resistance. Many companies partner with global leaders in sports surfacing to ensure top performance. Look for:

Use of certified materials such as IAAF-approved or GREENGUARD GOLD tracks

Customization options for colors, markings, and layouts

Modern equipment for precise application

Warranties on materials and workmanship

You deserve clear communication and a transparent pricing structure from your track resurfacing company. Leading companies provide upfront cost estimates, explain all service options, and keep you updated throughout the project. Many use project management tools and regular updates to ensure you always know the status of your resurfacing. The table below shows some best practices:

| Practice | Benefit |

|---|---|

| Clear cost estimates | No hidden fees, easy budgeting |

| Project dashboards | Real-time progress tracking |

| Regular updates | Keeps you informed and involved |

| Certifications and warranties | Builds trust and confidence |

Note: Good communication helps you avoid surprises and ensures your project stays on track.

You keep your running track in top shape by cleaning it regularly. Dirt, leaves, and debris can grind into the surface and cause damage if left unchecked. You should sweep or use a leaf blower at least once a week. If your track sees heavy use, increase cleaning to two or three times per week. Remove debris right away to prevent it from sticking or staining.

Sweep or blow off dirt, leaves, and grit weekly.

Spot clean spills as soon as they happen.

Use mild soap and water for stains. Avoid harsh chemicals.

Check drains and clear them to prevent water pooling.

Protect the track with mats or boards when moving equipment or vehicles.

Tip: Develop a cleaning schedule that matches your track’s usage and weather conditions. Consistent cleaning helps prevent premature wear and keeps the surface safe for athletes.

You can stop small problems from turning into big ones by making preventive repairs. Inspect your track often for cracks, loose seams, or bubbling. Patch small cracks and holes right away. Polyurethane resin injection works well for minor cracks, while heat fusion repairs handle weather-related damage.

Inspect the track for damage every week.

Patch minor cracks and holes promptly.

Monitor high-traffic areas for early signs of wear.

Remove debris from track edges to prevent buildup.

Schedule seasonal inspections to catch issues early.

Note: Professional repair services usually last longer and provide better safety than DIY fixes.

You should schedule regular professional maintenance to keep your track performing at its best. Experts use the right tools and methods to clean, inspect, and repair your surface. Professional care ensures your track stays safe, lasts longer, and saves you money in the long run.

Routine cleaning and debris removal prevent slips and surface damage.

Regular inspections catch wear or damage before it spreads.

Deep cleaning every 3–4 years revitalizes the track and preserves its health.

Professional repairs and resurfacing extend the track’s lifespan and reduce costly replacements.

Callout: Professional maintenance protects athletes, supports community use, and helps your track last for many years.

You now understand the essentials of running track resurfacing in 2025.

Costs range widely, depending on size, materials, and site conditions.

The process includes assessment, preparation, application, and careful curing—usually 7–10 days before use.

Good maintenance, like regular cleaning and prompt repairs, extends your track’s life.

Choose experienced contractors who use proper methods and materials.

To get the best results:

Define your project scope and involve all stakeholders.

Schedule professional inspections and review your track’s history.

Request detailed quotes and clear project plans from trusted resurfacing companies.

Timely resurfacing and smart maintenance keep your facility safe, durable, and ready for athletes.

You should resurface your running track every 8 to 15 years. The exact timing depends on usage, weather, and material quality. Regular inspections help you spot early signs of wear.

Polyurethane remains the top choice in 2025. It offers long life, strong weather resistance, and excellent performance. Rubberized surfaces also work well for schools and community tracks.

No, you cannot use the track during resurfacing. Crews need the area clear for safety and quality. Most projects take 2 to 8 weeks, depending on size and weather.

Sweep or blow off debris weekly.

Clean stains with mild soap and water.

Inspect for cracks or damage often.

Schedule professional maintenance every year.

Consistent care helps your track last longer and stay safe.

Resurfacing alone does not solve drainage issues. You need to repair or upgrade the base and drainage system before applying a new surface. Proper drainage protects your investment and prevents future damage.