Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

If you wonder how much does a rubber running track cost in 2025, you will find that prices range from $300,000 to $1,200,000. Factors like track material, size, and installation steps can make a big difference. For example, the surface, site work, and extra features all add to the total. Huadong Track offers three main options: GOMER, GOTER, and GODER prefabricated tracks. Each one uses eco-friendly materials and offers a long service life. You can ask Huadong Track for a custom quote to match your needs.

Rubber running track costs in 2025 can be $50,000 or up to $1,200,000. The price depends on size, materials, and how it is installed.

Regular maintenance is very important. It makes the track last longer. It also stops expensive repairs from happening later.

Picking the right materials can help you save money over time. Better materials cost more at first but need less fixing.

Ask for quotes from many companies. This lets you compare prices. You can find the best deal for your project.

Look at funding choices and grants to help pay for costs. Many programs give money to community sports projects.

When you plan a new rubber running track, you probably want to know how much does a rubber running track cost in 2025. The answer depends on several factors, but you can expect the total price to range from $50,000 to $1,200,000. Most projects fall between $300,000 and $1,200,000 for a standard 400-meter track. If you look at the cost per square meter, you will see prices from $16 to $34. Resurfacing an existing track usually costs between $60,000 and $180,000.

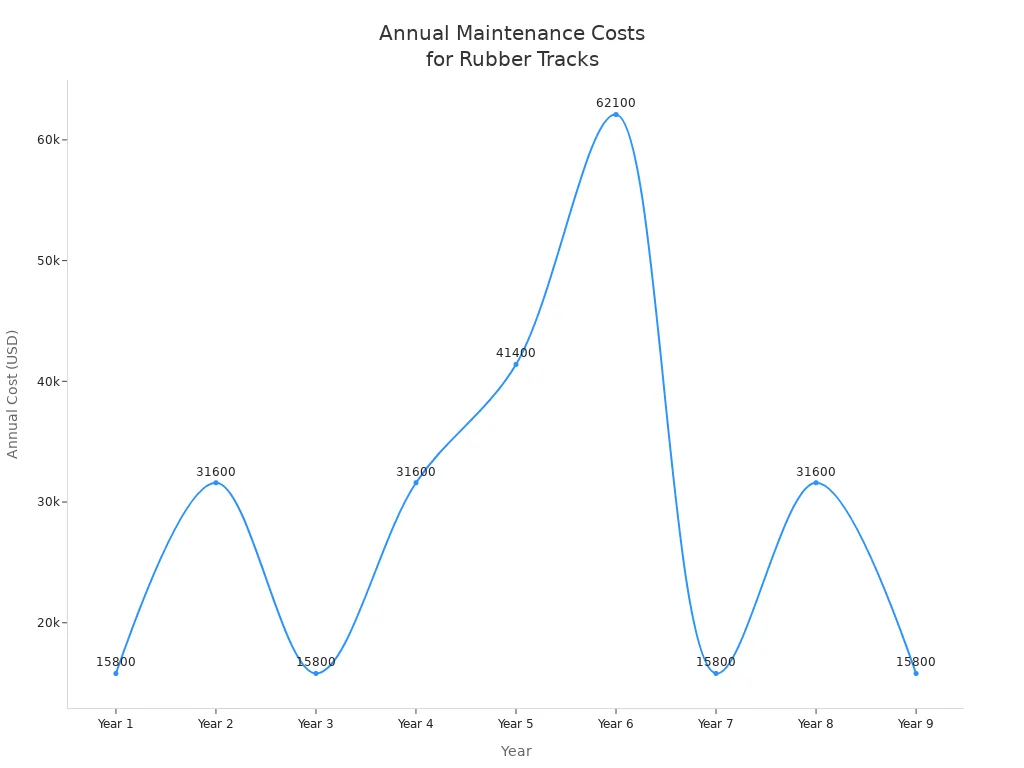

You should also think about ongoing maintenance. Regular care keeps your synthetic rubber running track in top shape and helps it last longer. The table below shows typical maintenance costs over nine years:

Year | Regular Maintenance | Deep Clean | Repairs | Line Marking | Annual Cost |

|---|---|---|---|---|---|

1 | $15,800 | N/A | N/A | N/A | $15,800 |

2 | $15,800 | $15,800 | N/A | N/A | $31,600 |

3 | $15,800 | N/A | N/A | N/A | $15,800 |

4 | $15,800 | $15,800 | N/A | N/A | $31,600 |

5 | $15,800 | N/A | $25,600 | N/A | $41,400 |

6 | $15,800 | $15,800 | N/A | $30,500 | $62,100 |

7 | $15,800 | N/A | N/A | N/A | $15,800 |

8 | $15,800 | $15,800 | N/A | N/A | $31,600 |

9 | $15,800 | N/A | N/A | N/A | $15,800 |

Total Cost | $142,200 | $63,200 | $25,600 | $30,500 | $261,500 |

Avg Annual Cost | N/A | N/A | N/A | N/A | $29,055 |

Tip: Regular maintenance helps you avoid bigger repair bills later and keeps your track safe for everyone.

The cost of a rubber running track depends on many things. You need to look at the size, the materials, and the number of tracks you want to build. Here are the main factors that affect the cost of a rubber running track:

Factor Type | Description |

|---|---|

Market Drivers | Elements that stimulate demand for rubber running tracks. |

Trends | Current movements in the market affecting pricing. |

Restraints | Challenges that may limit market growth, such as high installation costs. |

Opportunities | Potential areas for growth in the market. |

Raw Material Costs | Expenses related to sourcing rubber materials. |

Installation Costs | Costs incurred during the setup of the tracks. |

Maintenance Needs | Ongoing expenses for upkeep of the tracks. |

Competition | Influence of alternative surfaces on pricing strategies. |

Larger tracks with more lanes cost more to build. For example, an eight-lane track will be more expensive than a six-lane track because it uses more materials and takes more time to install.

The type of material you choose also changes the price. Synthetic rubber running track surfaces, like polyurethane or EPDM, often cost more but last longer and need less maintenance.

High-quality rubber materials raise the cost of a rubber running track, but they give you better performance and durability.

If you order more than one track or buy in bulk, you might get a lower price per unit.

High installation costs can be a barrier for some schools or communities. Budget limits in some areas may also affect your choices.

You should also consider the different product options. Huadong Track offers three main types of synthetic rubber running track surfaces:

GOMER Prefabricated Environmental Rubber Track: This track uses a double-layer design with a 4mm color surface and a 9mm gray bottom. It is eco-friendly and meets top industry standards. The warranty lasts up to 10 years.

GOTER Prefabricated Environmental Rubber Track: Both the surface and bottom layers use pure natural rubber with safe additives. This track can last up to 20 years.

GODER Prefabricated Rubber Running Track: This option also uses a double-layer design. The surface is 4mm thick, and the bottom is 9mm. It combines natural and synthetic rubber for a lifespan of about 15 years.

Note: Choosing the right type of synthetic rubber running track can help you balance cost, durability, and environmental impact.

When you plan your project, always ask for a detailed quote. This helps you understand the full rubber running track cost and avoid surprises later.

There are different choices for running track surfaces. Each one changes how much you pay and how the track works. The table below shows the main types you can pick in 2025:

Track Type | Description | Cost Consideration |

|---|---|---|

Paved-in-place track system | Two layers with EPDM polyurethane on top. It is strong but not very soft. | Usually costs less than prefabricated tracks. |

Sandwich track system | Like paved-in-place, but has crowned layers for a better hold. | Costs are in the middle. Good for schools and colleges. |

Full-pour polyurethane track | Made with polyurethane and recycled rubber. It gives more support. | Costs more because of the materials. |

Pre-fabricated rubber tracks | High-quality and meets all rules. This is the priciest choice. | Great for big competitions, but not cheap. |

You should think about how long the track will last and how it performs. Polyurethane tracks can last 15 to 20 years. They are good at absorbing shock. Prefabricated rubber tracks are tough and bounce back well. They last 10 to 15 years. Latex tracks are cheaper but do not last as long.

Huadong Track has three main products for synthetic rubber running track jobs:

GOMER Prefabricated Environmental Rubber Track has a 4mm colored top and a 9mm gray bottom. It is eco-friendly, meets IAAF Class 1, and has a 10-year warranty.

GOTER Prefabricated Environmental Rubber Track uses only natural rubber and safe extras. It can last up to 20 years.

GODER Prefabricated Rubber Running Track mixes natural and synthetic rubber in two layers. It lasts about 15 years.

These choices help you find the right mix of price, strength, and being good for the planet.

How hard it is to install the track changes the cost. Some tracks need more steps and more work. For example, water-based porous tracks need 10 or 11 steps. They are also affected by the weather. This means more work and higher costs. Non-porous tracks have fewer steps. They are easier to put in, so they cost less.

Track Type | Installation Complexity | Labor Sensitivity | Cost Implication |

|---|---|---|---|

Water-based Porous | 10 to 11 steps | High (weather-dependent) | Higher due to labor intensity |

Non-Porous | Fewer steps | Low (less sensitive) | Lower due to easier installation |

If you are replacing an old track, you need to remove and throw away the old one. This adds to your total cost.

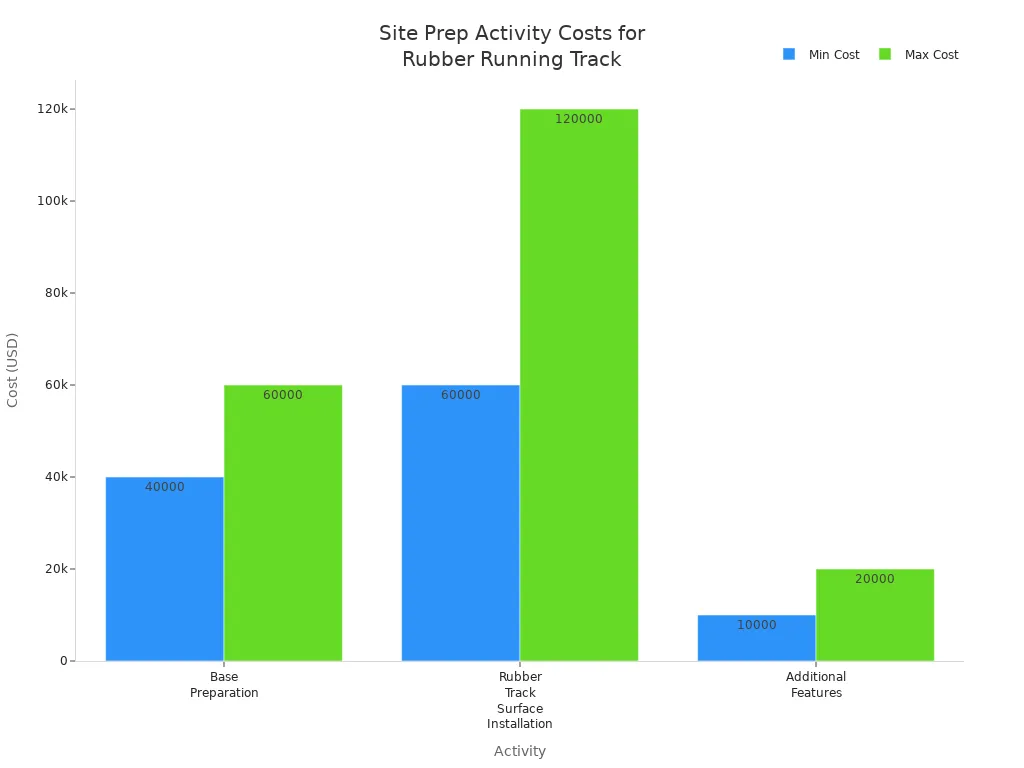

Getting the site ready is a big part of the cost. You must make the base, put down the synthetic rubber running track, and add things like drains and lines. The table below shows what you might pay:

Activity | Cost Range |

|---|---|

Base Preparation | $40,000 - $60,000 |

Rubber Track Surface Installation | $60,000 - $120,000 |

Additional Features (e.g., drainage, markings) | $10,000 - $20,000 |

Total Estimated Cost | $150,000 - $300,000 |

You might pay more if your ground is bad or needs special drains. Good drains keep your synthetic rubber running track dry and safe. The kind of base you use also changes the price.

Tip: Always check your ground before you start. This helps you avoid problems and keeps your running track construction costs under control.

You might want to know how much it costs to resurface a running track in 2025. Most resurfacing jobs cost between $60,000 and $180,000. The price changes based on the size of your rubber running track and the materials you pick. You can use a running track resurfacing cost calculator to get a fast estimate. Resurfacing fixes your synthetic rubber running track without needing a full rebuild. This keeps your facility safe and helps your track last longer.

Tip: Resurfacing is a good way to fix cracks and worn spots. It also makes the track safer and better for everyone who uses it.

Many things can change how much it costs to resurface a running track. You should think about these main things:

Choice of Materials: The kind of synthetic material, like polyurethane or rubberized surfaces, changes the price. Better materials last longer but cost more.

Installation Labor: Harder jobs need more skilled workers. This makes the total cost go up.

Long-term Maintenance Requirements: Some materials need more care over time. This can affect your budget later.

Track Specifications: Extra lanes or special features make the final price higher.

The shape of your current rubber running track matters too. If you take care of your track, resurfacing costs less. If there is a lot of damage or deep cracks, you might need extra repairs, which adds to the price. Doing regular maintenance helps you avoid big repairs and keeps your synthetic rubber running track in good shape.

Here are some good things about regular care:

Resurfacing brings back the surface without the cost of a full rebuild.

A clean surface keeps athletes safe and lowers the chance of injuries.

Places that take care of their tracks spend less money over time and have fewer problems.

Huadong Track has three main products for resurfacing or new tracks:

GOMER Prefabricated Environmental Rubber Track: Double-layer, eco-friendly, and has up to 10 years warranty.

GOTER Prefabricated Environmental Rubber Track: Made from pure natural rubber and lasts up to 20 years.

GODER Prefabricated Rubber Running Track: Double-layer, uses natural and synthetic rubber, and lasts 15 years.

Regular care and picking the right materials help you save money and keep your track looking nice.

You might wonder, how much does a rubber running track cost for your place? To find out, you need to follow some important steps. Each step helps you know the total rubber running track cost and stops surprises later.

Select Material Type and Quality

Pick if you want latex, polyurethane, or a hybrid surface. Each one costs a different amount and lasts a different time. Polyurethane and hybrid tracks last longer but cost more at first.

Measure Track Size and Lane Width

Bigger tracks and more lanes make the price go up. Most people use a 400-meter track, but you should check your space and pick how many lanes you want.

Check Site Preparation and Base Condition

Look at the ground where you want to build. If the base is broken, you may need to fix it before you start. Good site work keeps your synthetic rubber running track safe and helps it last.

Calculate Labor Costs and Location Impact

Labor costs change in different places. Some areas pay workers more, so your total cost can be higher.

Add Features and Equipment

Think about extras like lane lines, lights, or drains. These things add to the rubber running track cost but make the track safer and easier to use.

Review Regulatory Needs and Timing

You might need permits or checks. Delays can make the price go up, so plan your time well.

Tip: Try a running track cost calculator for a fast estimate. These tools let you put in your track size, material, and location. You get a custom estimate in just two minutes. Schools, sports clubs, and private places use these tools to plan their money. Project managers like Leo Casas from American University say these calculators save time and help stop mistakes.

Feature | Description |

|---|---|

Instant Estimate | Get a custom cost estimate in just two minutes using real data. |

Target Audience | Made for schools, towns, sports clubs, and private places. |

User Feedback | Project managers and planners give good reviews. |

You should also check out the main product choices from Huadong Track. Each one has different good points:

GOMER Prefabricated Environmental Rubber Track: This track has a 4mm color top and a 9mm gray bottom in two layers. It is eco-friendly and meets top rules. GOMER is the only material used for the main and side tracks at the Incheon Asian Games and has the IAAF Class 1 Facility Certificate. The warranty is up to 10 years.

GOTER Prefabricated Environmental Rubber Track: Both layers use pure natural rubber with safe extras. This track can last up to 20 years.

GODER Prefabricated Rubber Running Track: This one uses two layers with a 4mm top and a 9mm bottom. It mixes natural and synthetic rubber and lasts about 15 years.

You can spend less on your running track and still get good quality. Here are some smart ways to save money:

Use Value Engineering

Work with your builder and designer to change the plan. You can switch materials or building steps to lower costs but keep the track safe and strong.

Get Multiple Quotes

Ask for detailed prices from a few companies. Compare costs, warranties, and experience. Do not pick the cheapest without checking the quality.

Plan for the Long Term

Choose materials that last longer, even if they cost more at first. This saves money on fixes and resurfacing later.

Avoid Common Mistakes

Do not pick the cheapest company. Low prices can mean bad work and more repairs.

Do not think all companies are the same. Some have more experience and better safety.

Always check for warranties. A good warranty means the company trusts its work.

Explore Funding and Grants

Start with a clear project price. Look for help from local groups, alumni, or booster clubs. Many grants help pay for sports places, including running tracks.

Grant Program | Application Dates | Funding Amount |

|---|---|---|

Tire Stewardship BC | Opens February 5, 2024 | Up to $30,000 |

Kal Tire – Kal’s Replay Fund | Opens January 4, 2024 | Competitive grants |

Funding Source | Description |

|---|---|

Land and Water Conservation Fund | Helps pay for outdoor projects, like running tracks. |

EPA Brown / Greenfield Program | Helps fix land for new buildings. |

Community Facilities Direct Loan & Grant Program | Gives loans and grants for community sports projects. |

Community Development Block Grant Program | Pays for community projects, including sports places. |

Outdoor Recreation Legacy Partnership Program | Improves outdoor fun, may help pay for running tracks. |

You can also work with local builders or parks departments. Some offer public-private deals or special payment plans.

Banks and credit unions may give business loans with lower rates. Some builders offer payment plans for synthetic rubber running track jobs.

Note: Always talk to a trusted company like Huadong Track for a custom price. Their team can help you plan, budget, and pick the best surface for your needs.

If you follow these steps and tips, you can answer, how much does a rubber running track cost, with confidence. Good planning and smart choices help you control your rubber running track cost and build a safe, long-lasting place.

You have learned that a rubber running track in 2025 costs between $50,000 and $1,200,000. The price depends on things like the materials, the size, and how it is installed. Every project is different because prices change, new technology comes out, and people want different things. You need a special estimate for your project.

Getting a custom estimate helps you:

Stay updated on price changes.

Find what works best for your location.

Pick the right materials for your synthetic rubber running track.

If you contact Huadong Track, you get expert help and a quote made just for you.

Step | Description |

|---|---|

1 | Tell them about your project. |

2 | Huadong’s team helps you choose the best flooring. |

3 | You get a special price for your rubber running track. |

To get ready for your project, do these things: First, hire a designer who knows what they are doing. Next, pick a builder who has finished at least six jobs like this. Then, make a list of what you want on your track. Last, choose strong design details so your track lasts a long time.

Huadong Track has GOMER, GOTER, and GODER prefabricated tracks. All of them meet high standards and last many years. Always follow the rules for cleaning and taking care of your running track. This keeps your yearly cleaning and maintenance costs low.

You can expect a rubber running track to last 10 to 20 years. GOMER tracks last up to 10 years. GOTER tracks can last 20 years. GODER tracks offer about 15 years of use.

You should choose the material based on your needs. GOMER uses eco-friendly layers. GOTER uses pure natural rubber. GODER combines natural and synthetic rubber. Each type offers strong performance and long life.

You should resurface your track every 8 to 12 years. Regular cleaning and care help your track last longer. If you see cracks or wear, plan for resurfacing soon.

Yes, weather can change installation costs. Wet or cold weather may slow down work. This can increase labor costs. Always plan your project during dry, mild seasons for the best results.

Yes, you can ask Huadong Track for a custom quote. Share your project details. Their team will help you pick the right product and give you a price that fits your needs.