Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

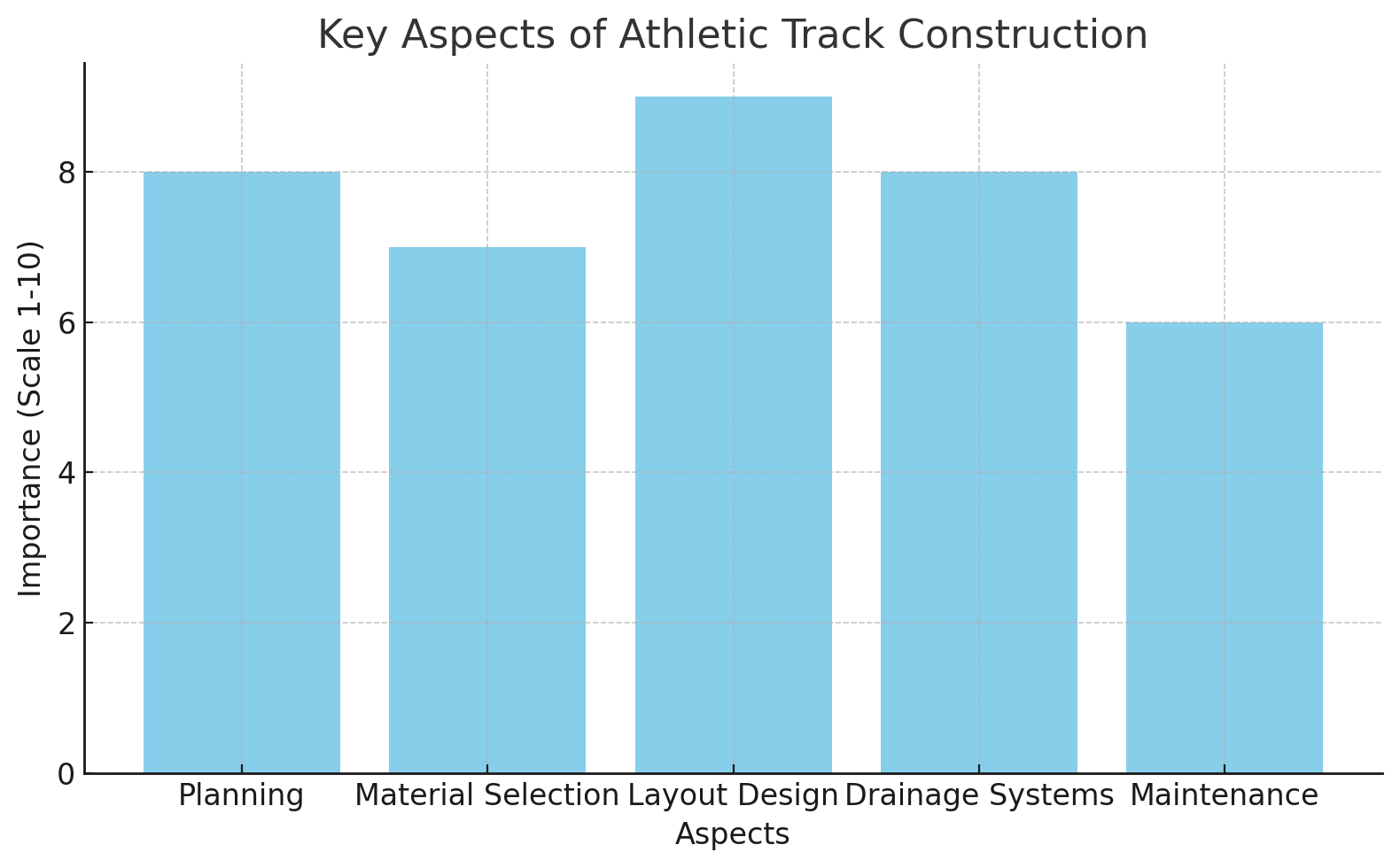

Athletic tracks play a crucial role in sports and competitions. Their construction directly impacts performance and safety. In this article, we'll explore the essential aspects of athletic track construction, including design, material selection, technical specifications, and maintenance. By the end, you'll understand how proper construction ensures fairness and longevity for athletes.

The standard athletic track construction typically follows a 400-meter design. This design includes two straightaways and two curved sections, creating a balanced and fair layout for competitors. The straightaways and curves are symmetrically positioned to ensure that all athletes run on the same type of surface and under similar conditions, promoting fairness.

The track’s lanes are arranged to allow optimal performance, with the curve radius ensuring athletes’ centripetal force is properly managed. This is crucial because tight or irregular curves can affect an athlete’s speed and safety.

A critical component of track construction is accurate measurement and marking. The length of a track is measured from the outer edge of the boundary, with a 30cm extension for tracks with no physical edge. Precision in marking lanes is essential to ensure that each lane maintains the correct distance for competitive events. Each lane width must adhere to international standards, typically between 1.22 to 1.25 meters, to maintain consistency across various events.

Choosing the right materials for athletic track construction plays a vital role in ensuring long-term durability and performance. Common materials include asphalt, concrete, and more specialized options like scoria cinder.

● Asphalt: Often used for budget-friendly options, asphalt offers flexibility and longevity, especially when combined with a suitable base.

● Concrete: More expensive but provides excellent durability and stability, especially in heavy-use facilities.

● Scoria Cinder: Used in more affordable and specialized tracks, this volcanic material offers natural resilience and better drainage.

For precise athletic track construction, maintaining uniformity in track specifications is crucial. Lane widths should range from 1.22 to 1.25 meters, and the lines separating lanes must be uniform across the surface. This is particularly important in ensuring that every track provides an equal racing environment, with no variance in lane dimensions.

The elastic modulus (the stiffness of the track surface) must also be consistent across all lanes to avoid discrepancies in performance. This ensures that athletes have the same experience, no matter which lane they run in.

Tracks must maintain specific slope requirements to optimize athlete performance and ensure safety. For straight sections, the horizontal gradient should be no more than 5‰, while curves can have a slightly steeper slope at 8‰. Longitudinal slopes should be kept under 1‰ to avoid water accumulation.

Special areas like the high-jump zone require a slope of no more than 0.4% to maintain fair conditions for competitors. Using advanced technologies like laser leveling ensures that these slopes are precisely maintained during the construction phase.

Safety is a top priority in athletic track construction. The surface must be designed to absorb impacts without compromising traction. For example, the surface must have an impact absorption rate of 35%-50%, while also ensuring that vertical deformation remains within 0.6-1.8mm. These parameters are essential for preventing injuries and improving athletes’ comfort during training or competitions.

The foundation of the track is the key to its long-term stability. A well-constructed sub-base, typically made from compacted gravel or crushed stone, ensures effective drainage and minimizes surface cracking. The base layer, made from materials like asphalt or cement, provides a solid foundation for the track surface. The choice between asphalt and concrete depends on budget and durability requirements, with asphalt being a more cost-effective option for many projects.

Proper drainage is essential for preventing water damage and ensuring the track remains in excellent condition. Tracks often incorporate a turtle-back double-slope drainage design, which directs water into a circular blind ditch and water collection system. This system is capable of handling heavy rainfall, ensuring that the track remains usable within hours of a downpour.

The surface of the track is typically built using a layered spraying method. This involves applying a composite structure that includes a bottom 13mm EPDM particle mixed layer and a 3mm full-plastic self-tie top layer. This method ensures that the track surface meets the required Shore hardness (45-60°), providing excellent performance for athletes during races.

The surface is designed for optimal impact absorption and low vertical deformation to reduce strain on athletes’ bodies, improving both safety and comfort.

In today's world, environmental considerations are a significant part of athletic track construction. Compliance with regulations regarding volatile organic compounds (VOC) and heavy metal content is critical. The track material must meet the standards for safety and sustainability. For instance, solid raw materials used in track surfaces must have VOC content lower than 5g/L, ensuring that the track is both safe for athletes and environmentally friendly.

Once the surface material is laid, it must be cured correctly to achieve the required hardness and elasticity. Curing times and temperature controls are essential in ensuring that the track surface meets international competition standards. This process ensures that the track remains durable and functional over its lifespan.

The cost of athletic track construction varies significantly depending on the materials used and the complexity of the project. A basic asphalt track may cost around $650,000, while a more durable post-tension concrete track could run as high as $1.5 million. The overall cost will be influenced by factors such as drainage system installation, track surface type, and site preparation requirements.

Track maintenance should also be factored into the total budget. While initial construction costs may be significant, long-term maintenance and resurfacing are essential for preserving the track’s performance and safety. Resurfacing typically occurs every 8 to 10 years, and it’s essential to budget for routine inspections, cleaning, and minor repairs.

Choosing the correct track size is essential for meeting both space and competition requirements. The standard 400-meter track is suitable for most professional athletic events, but smaller tracks (such as 300m or 200m) may be used in areas with limited space or for training purposes. Factors such as land availability and the primary purpose of the track (training vs. competition) will determine the appropriate design.

Customization is key when designing tracks for specific needs. Whether it’s for high schools, universities, or professional athletic facilities, the track must meet the specific requirements of the users. For example, indoor tracks typically use different materials and surface types than outdoor tracks, often incorporating banked curves to enhance performance.

In conclusion, athletic track construction is a complex process that demands careful planning, material selection, and adherence to strict technical specifications. The track layout, base materials, surface, and drainage systems all play key roles in ensuring a high-performance, safe, and durable facility. By understanding the construction process and selecting the right materials, track designers can create long-lasting tracks for competitive sports. Investing in quality construction and regular maintenance ensures lasting value for athletes, schools, and sports organizations.

Huadongtrack provides innovative track solutions that combine superior materials and cutting-edge technology, ensuring high performance and safety.

A: Athletic track construction involves careful planning, material selection, layout design, and adherence to technical specifications. The process ensures a safe, durable, and high-performance surface for athletes.

A: The choice of materials depends on factors like cost, durability, and location. Common options include asphalt, concrete, and scoria, each offering different performance and maintenance benefits.

A: Drainage systems prevent water damage and ensure the track remains usable in all weather conditions, contributing to the track’s longevity and athlete safety.

A: The cost varies depending on the track type and materials used, with prices ranging from $650,000 to $1.5 million for standard 400-meter tracks.

A: Regular maintenance, including resurfacing every 8 to 10 years, is essential to preserve the track's performance, safety, and durability.