Views: 0 Author: Site Editor Publish Time: 2025-09-07 Origin: Site

Indoor running tracks are becoming a vital part of sports facilities, offering year-round accessibility. The floor plays a critical role in ensuring athlete safety and performance. In this article, we’ll explore the types of indoor running track flooring, their benefits, and how to choose the best one for your needs.

Indoor running track flooring refers to the materials used to cover the surface of indoor running tracks. Unlike outdoor tracks, which may be made from asphalt or concrete, indoor tracks require specialized flooring that can support high-performance use. The flooring plays a key role in both the safety and performance of athletes by offering shock absorption, durability, and the right amount of grip.

Several materials are commonly used for indoor tracks, each with its own set of benefits:

● Polyurethane: Known for durability and smoothness, providing excellent shock absorption and energy return.

● Rubber: Flexible and shock-absorbing, ideal for multi-use facilities.

● Synthetic Options: Often made from materials like EPDM, these tracks are low-maintenance and highly durable.

Each flooring type offers specific benefits such as comfort, performance, and low maintenance.

Choosing the right floor material for your indoor running track affects more than just aesthetics. The correct indoor running track flooring impacts:

● Athlete performance: Proper flooring can enhance speed, endurance, and comfort.

● Injury prevention: A cushioned surface reduces stress on joints and muscles.

● Track longevity: Durable flooring helps to extend the track's lifespan, reducing the need for frequent resurfacing or replacement.

Polyurethane is one of the top choices for high-performance indoor tracks. It offers:

● Durability: Long-lasting under high foot traffic.

● Energy return: Helps athletes maintain their speed.

● Maintenance: Easy to clean and maintain, making it a great long-term investment.

Polyurethane tracks are ideal for competitions and training, as they provide consistent performance.

Rubber flooring is another popular choice, especially for recreational and multi-use tracks. It is known for:

● Shock absorption: Reduces impact on the knees and joints.

● Flexibility: Great for facilities that serve various sports and activities.

● Cost-effectiveness: An affordable option that still provides durability.

Rubber floors are great for facilities that need versatility but still want durability and comfort.

Synthetic options, including EPDM and vinyl, provide:

● Consistency: A smooth, even surface for a variety of athletic activities.

● Durability: Can withstand heavy foot traffic.

● Customization: Available in various colors and designs to match your facility’s needs.

Synthetic floors are a good choice for facilities with high-usage expectations.

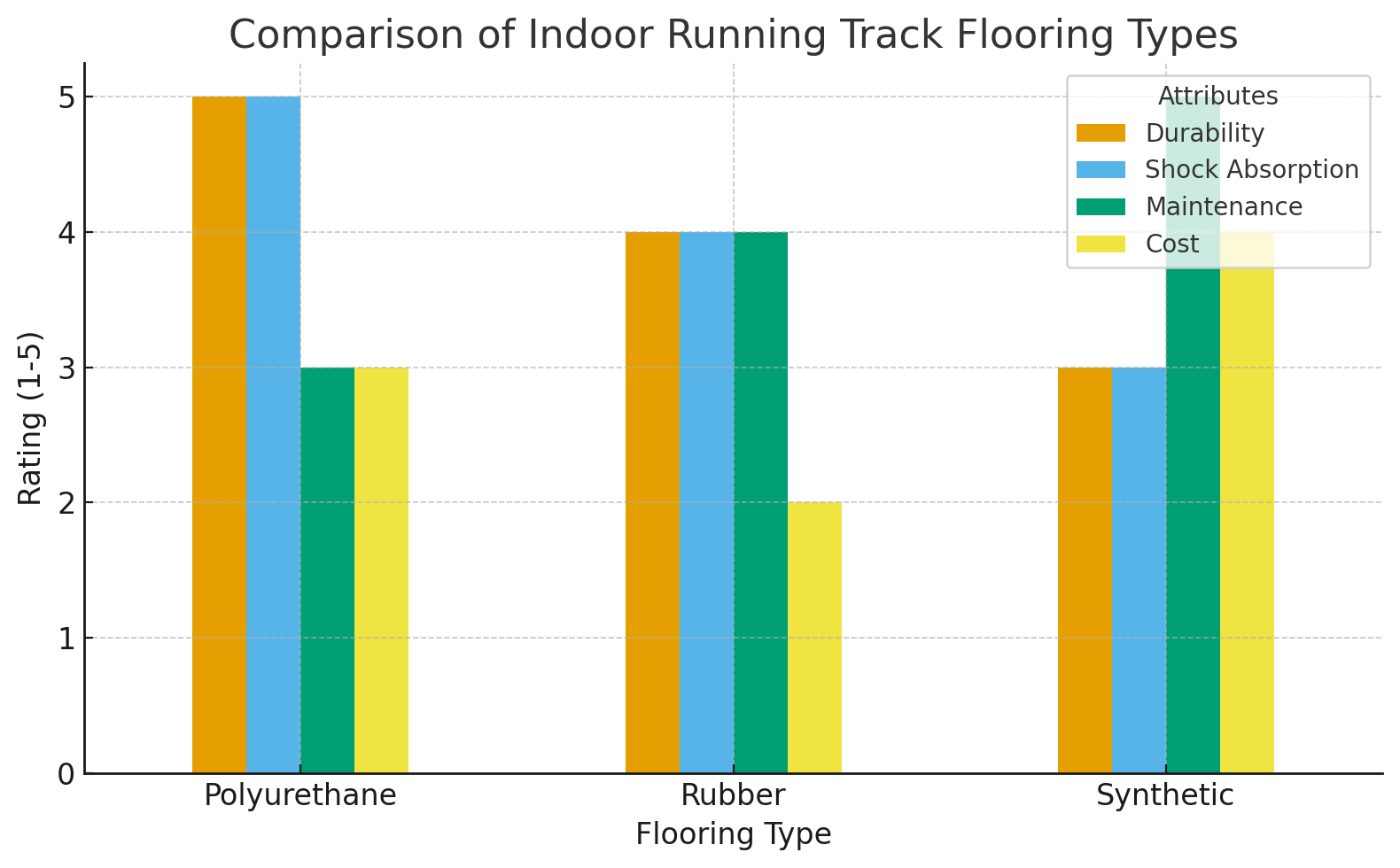

Material | Durability | Shock Absorption | Cost | Maintenance |

Polyurethane | High | Excellent | High | Low |

Rubber | Medium | Good | Medium | Medium |

Synthetic | High | Moderate | Low-Medium | Low |

The flooring choice depends on how the track will be used. For example:

● Professional training: High-performance floors like polyurethane are necessary.

● Recreational use: Rubber flooring is sufficient for lighter use.

The cost of indoor running track flooring can vary widely. Higher-end materials like polyurethane tend to be more expensive, while rubber and synthetic options offer more affordable choices. It’s important to balance performance and budget to get the best value for your facility.

Indoor climate and environmental factors can also affect flooring choices:

● Humidity and temperature: Some materials, like rubber, are more resilient in fluctuating conditions.

● Air quality: Some synthetic materials can emit volatile organic compounds (VOCs), so look for low-emission options.

The installation process depends on the material:

1. Site preparation: Ensuring a flat, clean surface.

2. Material application: For poured flooring like polyurethane, this step requires professional installation.

3. Finishing touches: Marking lanes and ensuring the surface is ready for use.

Indoor tracks require routine maintenance, including:

● Regular cleaning: Removing dust, dirt, and debris.

● Repairs: Fixing any surface issues before they worsen.

● Resurfacing: Some flooring options may need resurfacing after a few years, especially in high-traffic areas.

With proper maintenance, indoor running track flooring can last up to 10-15 years or more. Polyurethane tends to be the longest-lasting option, while rubber and synthetic floors may require resurfacing sooner.

A high-quality surface enhances:

● Traction: Allowing athletes to run faster and with greater comfort.

● Energy return: Helping athletes conserve energy during long workouts.

High-performance flooring offers:

● Shock absorption: Minimizing the risk of joint injuries.

● Stable surface: Reducing the chance of slips or falls.

Although high-quality flooring may come with a higher initial cost, it saves money in the long run by reducing the need for repairs and resurfacing. The durability of the flooring also reduces the likelihood of accidents, which can lead to expensive insurance claims.

Consider these factors when choosing the right flooring:

● Track usage: Will it be used for competitions or general fitness?

● Budget: Determine what you can afford.

● Maintenance: Choose a material that suits your ability to maintain it.

Some trusted flooring providers for indoor tracks include:

● Mondo Super X: Known for its high-performance and durability.

● PolyTurf Plus: A great option for heavy foot traffic.

Choosing a reputable brand ensures high-quality materials and professional installation.

Indoor running track flooring is essential for creating a high-performance and safe environment for athletes. By evaluating factors like material, cost, and usage, you can select the ideal flooring for your facility. Whether opting for polyurethane for professional training or rubber for recreational use, it's crucial to invest in quality flooring for long-term advantages. Consult professionals to make an informed decision and ensure a durable, top-performing track.

Huadongtrack offers expert solutions for high-quality flooring, providing long-lasting and reliable products for indoor tracks.

A: Indoor running track flooring is typically made of materials like polyurethane, rubber, or synthetic compounds. These materials offer durability, comfort, and safety for athletes.

A: Flooring is crucial for performance, safety, and injury prevention. It ensures consistent grip, shock absorption, and longevity for the track.

A: The cost varies depending on material, size, and usage needs. Polyurethane tends to be more expensive than rubber, but both provide long-term value.

A: Consider factors like track usage, budget, and material durability. Professional advice can help in selecting the best option for your facility's needs.

A: Regular cleaning and occasional resurfacing are key to maintaining the track. Proper care helps prolong the life of your flooring, reducing long-term costs.