A synthetic athletic track offers a smooth and resilient surface ideal for athletes. This type of synthetic athletic track utilizes materials such as polyurethane and rubber to ensure consistent performance. Schools, stadiums, and training centers often choose a synthetic athletic track because it helps athletes run faster and lowers the risk of injury. Unlike traditional surfaces, a synthetic athletic track delivers even traction. Modern running track designs frequently incorporate a synthetic athletic track to accommodate both casual runners and competitive athletes.

Synthetic athletic tracks use materials like polyurethane and rubber to create smooth, safe surfaces for running and sports.

These tracks improve athlete performance by providing a slight bounce and consistent grip, helping runners go faster and reduce fatigue.

Synthetic tracks protect athletes by absorbing shock, lowering the risk of injuries to joints and muscles.

They last much longer than traditional tracks, need less maintenance, and work well in all weather conditions.

Many schools, stadiums, and sports centers choose synthetic tracks for their durability, safety, and ability to support all levels of athletes.

A synthetic athletic track is a specially designed surface for running and athletic events. This type of running track uses advanced materials like polyurethane and rubber. These materials create a smooth, even, and slightly springy surface. The main goal of a synthetic athletic track is to provide athletes with a safe and consistent place to train and compete.

Note: Synthetic athletic tracks have replaced older surfaces like cinder or grass in many places. They offer better grip and reduce the risk of injury for runners.

Modern running tracks often feature a synthetic athletic track because it supports high performance. The surface absorbs shock, which helps protect athletes' joints and muscles. This makes it easier for runners to maintain speed and reduces fatigue during long events.

Synthetic athletic tracks appear in many types of athletic facility. Schools, colleges, and universities install these tracks for student athletes. Professional stadiums and sports complexes use them for national and international competitions. Community centers and local parks also choose synthetic tracks for public use.

Here are some common uses for a running track made from synthetic materials:

Track and field competitions, including sprints, hurdles, and relays

Training sessions for athletes at all levels

Physical education classes in schools

Recreational running and walking for the public

Hosting large events, such as marathons or athletic meets

A synthetic athletic track helps athletic facility managers provide a reliable surface for many activities. The running track stays usable in different weather conditions, which means fewer cancellations and more opportunities for athletes to practice. Synthetic tracks also support wheelchair racing and other adaptive sports, making them a key part of inclusive sports programs.

Synthetic track surfaces have become the standard for most major competitions. Athletes can trust the quality and consistency of the running track, which leads to better performance and fairer results.

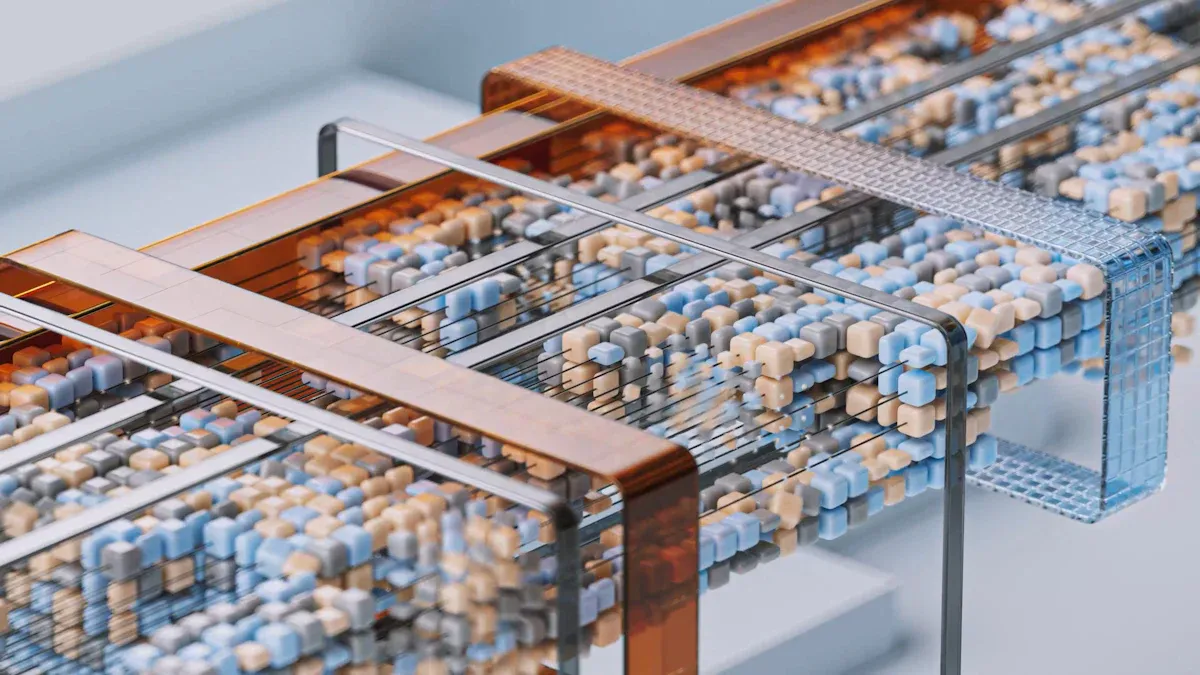

A polyurethane track forms the foundation of most modern track surfaces. Polyurethane is a type of plastic that starts as a liquid and hardens into a durable, flexible layer. This material creates a smooth and even running area. Many stadiums and schools choose a polyurethane track because it offers excellent shock absorption. Athletes feel a slight bounce with every step, which helps reduce stress on their legs and joints. Polyurethane also resists weather damage, so the track stays safe and usable in rain or heat.

Polyurethane track surfaces stand out for their long lifespan. Facility managers often select this material because it needs little maintenance. The surface does not crack or wear down quickly. Polyurethane track systems also allow for bright, visible lane markings. These features make the polyurethane track a top choice for both training and competition.

Tip: Polyurethane track surfaces help athletes achieve faster times by providing consistent grip and energy return.

Rubber plays a key role in synthetic track surfaces. Manufacturers often mix recycled rubber with polyurethane to create a softer, more forgiving running track surface. This blend adds extra cushioning, which further protects athletes from injuries. Rubber also improves traction, so runners can push off with confidence.

Other important materials include sand, fiber, and wax. Sand adds weight and stability to the track. Fiber strengthens the surface and prevents cracks. Wax helps the materials blend smoothly and gives the track a slight sheen. Together, these components create a running track surface that balances firmness with flexibility.

A well-designed synthetic track uses these materials to deliver a safe, high-performance experience. Track surfaces built with polyurethane and rubber support athletes at every level, from beginners to professionals.

Every running track begins with a strong foundation. Builders usually start by laying a base made of concrete or asphalt. This base gives the running track a flat and stable platform. A solid base helps prevent cracks and uneven spots on the track surfaces.

Drainage systems play a key role in the construction process. Engineers design these systems to move water away from the running track quickly. Good drainage keeps the running track surface dry and safe, even after heavy rain. Without proper drainage, water can collect under the track and cause damage over time. Facility managers often check the drainage system to make sure it works well throughout the year.

Tip: A well-built base and drainage system can extend the life of a running track and reduce repair costs.

After the base and drainage system are ready, workers add several layers to create the final running track surface. The first layer often includes a mix of rubber and polyurethane. This layer provides shock absorption and a slight bounce for athletes. Next, workers add more layers to build up the thickness and strength of the track surfaces. Each layer must cure or dry before the next one goes on.

There are two main ways to install these layers. In the poured-in-place system, workers mix the materials on-site and spread them evenly over the base. This method allows for a seamless finish and custom thickness. In the prefabricated system, manufacturers create large sheets of track material in a factory. Workers then roll out these sheets and glue them to the base. Prefabricated systems can speed up installation and ensure consistent quality.

Both methods produce a smooth, durable running track. The choice depends on the needs of the facility and the type of events it will host.

Before synthetic track surfaces became popular, most facilities used natural or basic materials for their running track. The three most common traditional types included cinder, clay, and asphalt. Cinder tracks used crushed coal or ash, which created a soft but uneven surface. Clay tracks offered a firmer base but often became slippery or muddy after rain. Asphalt tracks provided a hard, flat surface, but they lacked shock absorption and could become very hot in the sun.

Each traditional running track type had its own set of challenges. Cinder and clay tracks needed frequent maintenance. Rain could wash away parts of the surface, leaving holes or bumps. Asphalt tracks lasted longer but often caused more injuries because of their hardness. These older track surfaces did not support consistent athletic performance, especially during bad weather.

Synthetic running track surfaces have changed the way athletes train and compete. The main differences between synthetic and traditional tracks include:

Performance: Synthetic tracks provide a smooth, even surface. Athletes can run faster and with more confidence. The slight bounce in the surface helps improve athletic performance by returning energy with each step.

Durability: Synthetic running track surfaces last much longer than cinder, clay, or asphalt. They resist weather damage and need less maintenance. Facility managers can rely on these tracks for many years.

Safety: Synthetic tracks absorb shock, which protects athletes’ joints and reduces the risk of injury. Traditional tracks, especially asphalt, do not offer this protection.

Note: Many schools and stadiums now choose synthetic running track surfaces because they offer better results for both training and competition.

Synthetic tracks have set a new standard for modern sports facilities. They help athletes reach their best while keeping them safe and comfortable.

Synthetic tracks help athletes reach their best speeds. The surface gives a slight bounce, which returns energy to the runner’s legs. This feature supports better athletic performance during both training and competition. Runners feel less tired because the track absorbs some of the impact with each step. The even surface also allows for smooth strides and fewer slips. Coaches notice that athletes can focus more on their technique when they use high-quality running track surfaces.

Tip: Many world records in track and field have been set on synthetic tracks because of their consistent surface and energy return.

Safety stands as a top priority for any sports facility. Synthetic tracks protect athletes from common injuries. The shock-absorbing layers reduce stress on knees, ankles, and hips. This design lowers the risk of sprains, muscle strains, and joint pain. The track’s grip helps prevent slips, even in wet weather. Wheelchair racers and para-athletes also benefit from the smooth, stable surface. Schools and stadiums choose synthetic tracks to keep students and professionals safe during every event.

Shock absorption protects joints

Non-slip surface reduces falls

Consistent texture prevents uneven footing

Synthetic tracks last for many years with little upkeep. Most surfaces stay in good condition for 20 to 30 years. The materials resist damage from rain, sun, and temperature changes. Facility managers spend less time and money on repairs. Cleaning the track usually only requires sweeping or washing. Synthetic tracks do not crack or wear down quickly like older surfaces. This long lifespan makes them a smart investment for schools, parks, and stadiums.

| Feature | Synthetic Track | Traditional Track |

|---|---|---|

| Lifespan | 20-30 years | 5-10 years |

| Maintenance | Low | High |

| Weatherproof | Yes | No |

Note: A durable track means more time for athletes to train and compete, and fewer interruptions for repairs.

Synthetic athletic tracks use advanced materials like polyurethane and rubber to create safe, durable surfaces. Builders install these tracks with strong bases and drainage systems. Key benefits include improved performance, safety, and long lifespan.

Athletes gain better speed and comfort.

Facilities save on maintenance costs.

Synthetic tracks set the standard for modern sports. Future innovations will likely make running surfaces even safer and more efficient.

A synthetic athletic track uses advanced materials like polyurethane and rubber. These materials create a smooth, even running track surface. Older tracks, such as cinder or clay, often feel uneven and require more maintenance.

Most synthetic track surfaces last between 20 and 30 years. Facility managers choose these running track surfaces because they resist weather and need little maintenance. Regular cleaning helps extend the lifespan.

Modern running tracks offer better grip and shock absorption. These features help improve athletic performance and reduce injuries. Athletes trust high-quality running track surfaces for both training and competition.

Yes. Synthetic track surfaces drain water quickly and resist damage from rain or sun. This allows athletic facility managers to keep the running track open for use in most weather.

A polyurethane track uses polyurethane as its main material. Polyurethane creates a flexible, durable layer. This material helps the running track surface stay smooth and safe for athletes.

Tip: Regular inspections help keep track surfaces in top condition for every event.