Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

This document defines the minimum technical requirements for the design, construction and moisture control of reinforced concrete bases intended to receive the GODER® prefabricated synthetic athletic track system.

Compliance with these requirements is a pre-condition for:

The validity of the Huadongtrack product warranty for the GODER® system; and

Achieving the performance specified in World Athletics for synthetic athletic tracks.

These requirements apply to:

· 400 m standard running tracks and warm-up tracks;

· Run-ups, event areas and ancillary zones where the GODER® system will be installed.

Design and construct the concrete base, sub-base and drainage system in accordance with this document and the project drawings.

Provide all test results and as-built information to the Client and to Huadongtrack / the Track Installer.

Visually inspect the base and carry out simple tests prior to installation.

Confirm in writing whether the base is acceptable or describe any remedial measures required.

Ensure that these requirements are included in the civil works specifications and contracts.

Coordinate any design variations with Huadongtrack before construction.

The concrete base shall be designed and executed in accordance with relevant national standards and, where applicable:

· World Athletics – Track and Field Facilities Manual (latest edition)

· EN 14877:2013 – Synthetic surfaces for outdoor sports areas

· Good engineering practice for concrete slabs on grade in tropical, high-rainfall and high-groundwater conditions.

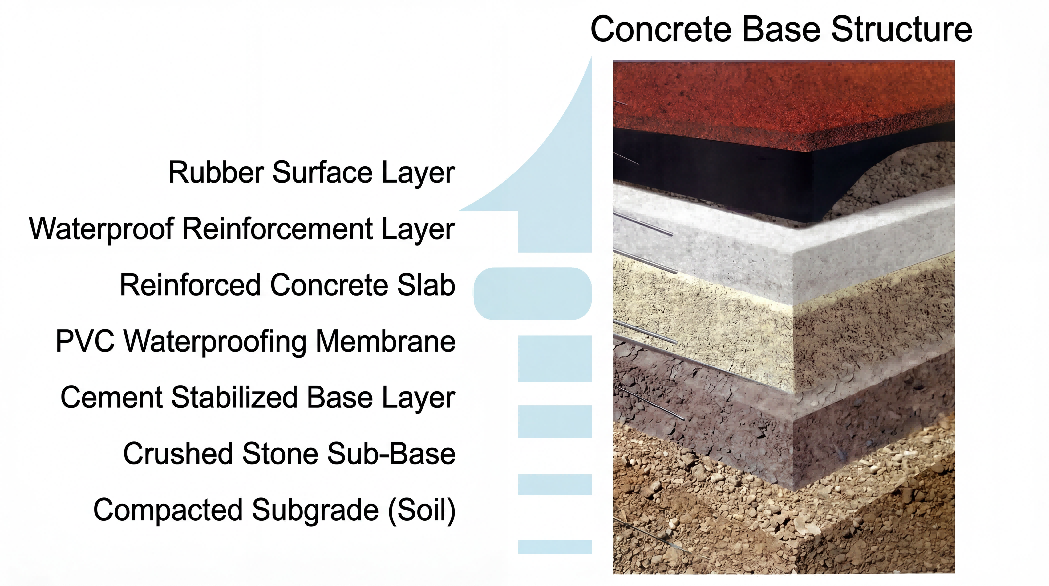

Reinforced concrete slab on a prepared and compacted sub-base, suitable for full bonding with a polyurethane adhesive and the GODER® prefabricated rubber track rolls.

Nominal structural thickness: 100–125 mm, unless otherwise specified by the structural design.

Thickness shall be consistent and adequate to carry all design loads without excessive cracking or settlement.

Minimum characteristic compressive strength: C25/30 (or ≥ 25 MPa at 28 days).

Maximum water–cement ratio: 0.55.

Air entrainment and admixtures shall be used as required to achieve workability and durability in the local climate.

Welded wire mesh (e.g. BRC A8 or equivalent) or rebar as per structural design.

Reinforcement positioned in the upper third of the slab thickness, with adequate cover (typically 30–40 mm).

Proper laps, anchorage and supports shall be provided to minimise cracking and avoid displacement during concreting.

Compacted crushed stone or gravel layer of adequate thickness as per design (generally 150–200 mm minimum).

Compaction to at least 95 % Modified Proctor or equivalent.

Sub-base shall be proof-rolled to identify and rectify soft spots.

Where not otherwise specified by the structural design, a typical base build-up suitable for the GODER® system may comprise:

Existing soil compacted and proof-rolled to achieve a firm, uniform bearing layer, free from soft spots and organic material.

Minimum 300 mm thick layer of graded crushed stone (nominal size 20–40 mm), placed and compacted in one or more layers.

Compaction by 10–12 t roller, with at least 5–8 passes at a speed of approx. 25–30 m/min, to achieve the required density (≥ 95 % Modified Proctor or equivalent).

Approx. 100 mm thick layer of cement-stabilised stone powder (or similar material), with cement content around 6 % by mass, mixed evenly on site by mechanical mixing equipment.

Compaction with 10–15 t roller to achieve a density of at least 95 %, thickness tolerance within ± 5 %, and a firm, stable surface without loose, soft or honeycombed areas.

The stabilised layer shall be cured for 2–3 days before concrete placement.

A high-quality PVC/HDPE waterproofing membrane may be installed above the stabilised layer to provide additional protection against rising moisture and to improve long-term stability of the system.

The membrane shall have fully sealed joints and be installed strictly in accordance with the manufacturer’s instructions.

Minimum 120 mm thick C25/30 (or higher) reinforced concrete slab, designed and detailed as per this document and project structural drawings.

Note: The exact layer thicknesses and materials shall be confirmed by the structural engineer and may be adjusted to suit local soil conditions and loading requirements.

Concrete mix design shall be carried out by an approved laboratory in accordance with relevant concrete standards.

Aggregates shall be clean, hard and durable, with mud content not exceeding:

Sand: max. 3 % by mass;

Coarse aggregate: max. 1 % by mass.

The use of low-shrinkage cement, reduced water–cement ratio, optimised aggregate grading and appropriate water-reducing admixtures is strongly recommended to minimise early-age cracking.

Typical slump values (for pumped concrete) may be:

At batching plant discharge: 18–22 cm;

At site during placement: 14–16 cm, adjusted for ambient temperature and transport time.

Batching equipment shall be calibrated regularly; aggregate moisture content shall be measured frequently and mix water dosage adjusted to maintain a consistent water–cement ratio.

On-site quality control shall include slump tests, compressive strength cubes and visual checks for segregation and bleeding.

Surface to be dense and closed, with wood-float or light broom finish, free of laitance, dusting and loose particles.

Power-trowel mirror or overly smooth finishes are not acceptable, as they reduce adhesive bond.

No curing compounds, sealers, paints or asphalt primers shall remain on the surface intended for bonding.

If such products are used, they must be completely removed by mechanical means (shot-blasting or grinding) prior to track installation, exposing sound, clean concrete.

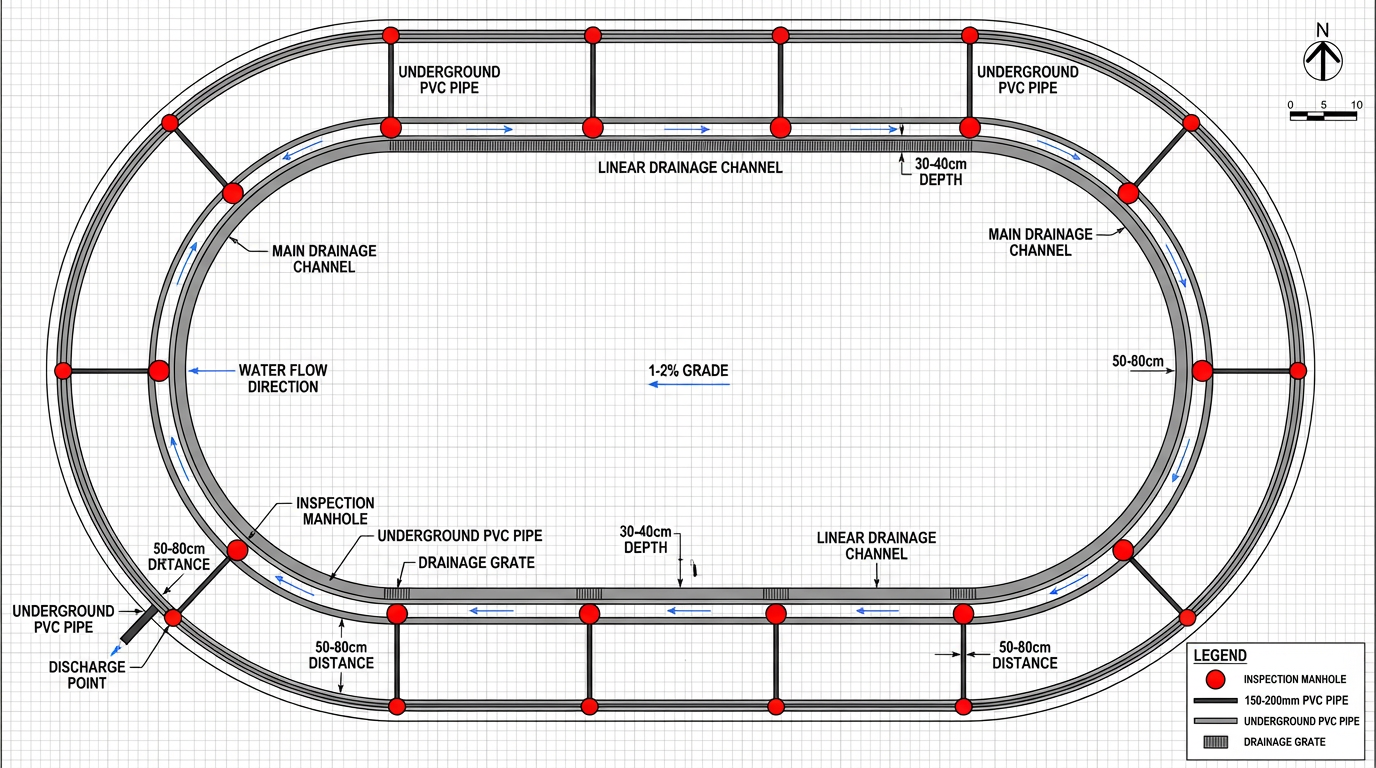

Cross-falls and longitudinal gradients shall ensure rapid surface drainage with no standing water on the concrete or on the finished track.

Typical recommended slopes:

Straight lanes: 0.5–0.8 % cross-fall.

Curves and surrounding areas: up to 1.0 %, uniform and without abrupt changes.

Final slopes shall comply with approved setting-out drawings and World Athletics guidelines.

When tested with a 3 m straightedge, the deviation shall not exceed:

· ± 6 mm under the straightedge at any position;

· Local irregularities not greater than 3 mm over 1 m.

High spots shall be rectified by grinding; low spots shall be filled with compatible cementitious levelling compounds to meet these tolerances.

Changes of level between the track, infield, sand pits, curbs and adjacent pavements shall be smooth and step-free.

Abrupt edges or steps that could damage the prefabricated rolls or create a safety hazard are not permitted.

Joint locations shall be planned to minimise reflection through the track surface (e.g. aligned with lane lines where practicable rather than across the lanes).

Construction joints shall be formed square, keyed as necessary and well supported.

Cold joints must be properly roughened and cleaned to ensure good bonding between pours.

Expansion and movement joints shall be provided at perimeters, around structures and at other critical interfaces in accordance with the structural design.

Joints shall be filled with flexible, non-bituminous sealants compatible with the polyurethane adhesive and track system.

The surface of joints must be flush; sealant shall not contaminate adjacent concrete surfaces.

If saw-cut joints are used, depth shall typically be approximately one-third of slab thickness, with spacing determined by the structural design.

Joints are intended to control cracking; their locations shall be coordinated with the track layout as far as practicable.

All visible cracks shall be assessed prior to track installation.

Active cracks or cracks wider than 0.3–0.5 mm shall be routed, cleaned and filled with appropriate structural repair materials (e.g. epoxy mortar or high-strength repair grouts).

Random, uncontrolled cracking is not acceptable; areas with extensive or unstable cracks may require slab replacement.

In locations with high rainfall and/or high groundwater levels (e.g. coastal tropical sites), special measures are essential to prevent moisture and vapour pressure from lifting the track or causing blistering and debonding.

Perimeter drains and internal sub-surface drains shall be provided as shown on the civil drawings, with sufficient capacity to lower the water level below the slab and to intercept lateral water flow.

Sub-surface drains (e.g. perforated pipes or strip drains such as 100 mm × 40 mm drain strips at approx. 5 m centres) shall be surrounded by free-draining aggregate and wrapped with filter geotextile to prevent clogging.

A capillary break layer (clean sand or fine gravel, thickness approx. 50 mm) may be placed directly under the slab to prevent capillary rise.

Where the design includes a geomembrane or waterproofing sheet:

It shall be installed on a smooth, compacted sub-base free of sharp objects;

Joints shall be fully taped or welded;

The membrane shall be protected by a sand or fine aggregate layer above (typically 50 mm) before concrete placement.

Any penetrations (drain pipes, columns, etc.) shall be sealed watertight.

Finished levels around the track shall slope away from the slab such that storm water is directed to drains, not towards the.3 Surface Water Management

Finished levels around the track shall slope away from the slab such that storm water is directed to drains, not towards the track.

No planting areas or soil banks shall be higher than the track edge in immediate proximity, to avoid washing soil onto the surface.

The drainage design shall aim to ensure that no hydrostatic water pressure exists under the concrete slab.

Standing water in trenches, under-slab voids or adjacent ditches must be kept below the underside of the slab at all times.

Concrete surfaces shall be moist-cured (e.g. water spray, wet burlap, curing blankets) to control shrinkage and ensure adequate strength and durability.

A minimum wet curing period of 10 days after placement is recommended, after which the slab shall be allowed to dry before running track installation.

Before installation of the prefabricated track, the concrete shall be at least 28 days old, and preferably older depending on climate and drying conditions.

The base must be clean, sound and dry, free from:

Dust, laitance and loose particles;

Oil, grease, fuel, bitumen, release agents or other contaminants;

Paint, markings, adhesives or any foreign coatings.

If contaminated, the surface shall be mechanically cleaned (shot-blasting or grinding) until sound concrete is exposed.

Damage caused by other trades (cuts, impact, chipping) shall be repaired before handover.

The slab shall not be used as a general access road for heavy vehicles without adequate protection.

Unless otherwise agreed with Huadongtrack, the concrete surface shall be prepared as follows prior to application of the polyurethane adhesive:

Use high-pressure water jet or other suitable mechanical means to remove laitance, weak surface layers, dust and contaminants, leaving a sound, slightly textured concrete surface.

Where efflorescence or strong surface alkalinity is evident, the surface may be treated with a dilute acid wash (e.g. approximately 8 % hydrochloric acid solution), applied uniformly to neutralise alkalinity and lightly etch the surface.

After etching, the surface shall be thoroughly rinsed with clean water to remove all residues and allowed to dry completely before proceeding.

The use of chemical etching shall be subject to approval by the Engineer and compliance with local regulations.

Low spots and minor depressions where water may pond shall be repaired using compatible cementitious or polyurethane-based patching compounds (e.g. PU mixed with fine rubber granules, or acrylic-emulsion with quartz sand and cement) to achieve the flatness requirements defined in Section 5.

Movement joints shall be cleaned, dried and filled with a flexible sealant compatible with the adhesive system.

The filled joint shall then be cut flush and, where required, a band of primer (e.g. 50–100 mm on each side) shall be applied over the joint zone prior to track installation, in accordance with the adhesive manufacturer’s recommendations.

A suitable polyurethane or epoxy-based primer / waterproofing base coat shall be applied to the entire concrete surface at the coverage rates recommended by the adhesive manufacturer, in order to:

Improve adhesion of the polyurethane adhesive;

Reduce residual dust;

Provide an additional moisture barrier.

Proper moisture control is critical for preventing blistering and debonding when using polyurethane adhesives.

At the time of installation, the concrete must be sufficiently dry. As guidance:

Moisture content by mass should be ≤ 4 %; and/or

In-situ relative humidity (RH) should be ≤ 75 % at 40–50 mm depth (where RH testing is available).

Plastic Sheet Test:

Tape a 1 m × 1 m clear polyethylene sheet onto the concrete surface with all edges sealed.

After 24 hours, there shall be:

· No visible condensation on the underside of the sheet; and

· No darkening of the concrete surface beneath the sheet.

Persistent condensation or darkening indicates excessive moisture; installation should be postponed and additional drying / mitigation measures considered.

Construction moisture remaining in the slab.

Groundwater or perched water under the slab where drainage or membranes are inadequate.

Water from cleaning, rain or adjacent higher areas draining towards the slab.

Visible free water on the base.

Saturated concrete or damp patches remaining after 24 hours of dry weather.

Rising damp visible as dark bands along joints or cracks.

Improve drainage and remove standing water in surrounding trenches.

Enhance ventilation and allow more drying time.

Where necessary and technically feasible, apply an approved moisture-mitigation system (e.g. epoxy moisture barrier) after consultation with Huadongtrack.

From completion of the concrete slab until installation of the track:

The slab shall not be used as a general access road or long-term storage area.

Fuel spills, oil leaks, paint works or bituminous products on the slab are strictly prohibited.

No additional chases or embedded services shall be cut into the slab without approval.

Heavy equipment (cranes, mobile platforms, scaffolding) shall be supported on boards or plates to distribute loads and prevent damage.

The surface shall be kept clean by regular sweeping; mud and construction debris shall be removed promptly.

Any contamination or damage caused during this period shall be rectified by the civil contractor at no cost to the track installer or manufacturer.

Before the GODER® prefabricated track system is installed, the concrete base shall be jointly inspected by the Engineer / Client, Civil Contractor and Huadongtrack / Track Installer.

As a minimum, the following items shall be confirmed in writing:

Base layout, levels and slopes are in accordance with approved drawings.

Surface finish, flatness and joints comply with Sections 5 and 6 of this document.

Sub-surface drainage and, where applicable, geomembrane / moisture barrier have been installed as designed.

Concrete is fully cured, structurally sound, clean and free of contamination.

Moisture conditions meet the criteria in Section 9, supported by test records or site tests.

All necessary repairs to cracks, joints and defects have been completed.

The base is handed over to the track installer in good condition and will be protected from further damage.